Zgjidhja e problemeve të rreshtimit të transmetimit Eaton Fuller

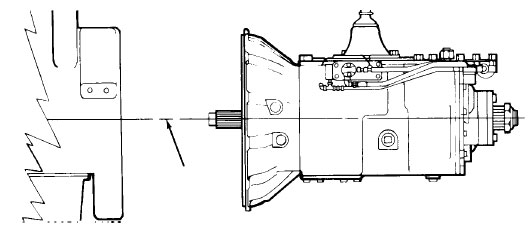

Harmonizimi koncentrik i Transmisionit të Engine

Shqetësimet e përbashkëta që rezultojnë nga misalignment

Direct slipout gear

Dështimi i kushinetës së ingranazhit

Parakohshme veshin input bosht vizore nga qendër e pasme e dy kthetrat pjatë

shtrirjes koncentrik

Shtrirja koncentrike do të thotë që motori dhe transmisioni duhet të kenë një bosht të përbashkët. Qëllimi i këtij seksioni është të përcaktojë procedurat që do të përdoren për të kontrolluar mosvendosjen e mundshme.

Instrumenti themelor i nevojshëm për marrjen e leximeve është një tregues i konferencës konike. Saktësia e leximeve është thelbësore për korrigjimin e problemeve të shtrirjes. Pastroni të gjitha sipërfaqet plotësisht përpara se të vazhdoni.

Kur të marrë lexime mëposhtme, rrotullohen motor me dorë, mos e fik motorin me motorin startues. Hiqni kandelet në motorët me benzinë, dhe lëshimi i kompresimit në motorët me naftë.

shënim: Para se të thirrni duke treguar volantin e motorit ose strehimin e volantit, sigurohuni që boshti i boshtit të motorit të mos ketë lojë të tepërt në fund. Nëse e bën atë, leximet e sakta nuk mund të merren. Vendosni gishtin tregues kundër volantit. Forconi boshtin bosht me gunga mbrapa dhe me radhë. Nëse lëvizja e luajtjes në fund tejkalon maksimumin siç përcaktohet nga prodhuesi i motorit, ajo do të duhet të korrigjohet.

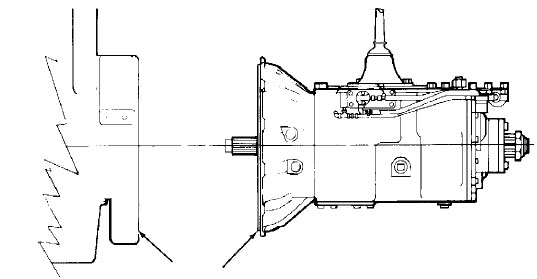

housings veshur

Kontrolloni për pilot të konsumuar ose të lodhur si në strehën e tufës së transmisionit ashtu edhe në atë të volantit të motorit. 1/4″ buza pilot e strehimit të tufës së transmisionit mund të vishet në strehën e volantit ose duke lehtësuar transmetimin ose pas kilometrazhit të lartë vetëm nga rruga dhe dridhjet e motorit.

Çdo sasi e konsiderueshme e veshjes në secilën pjesë do të shkaktojë keqvendosje dhe pjesa duhet të zëvendësohet.

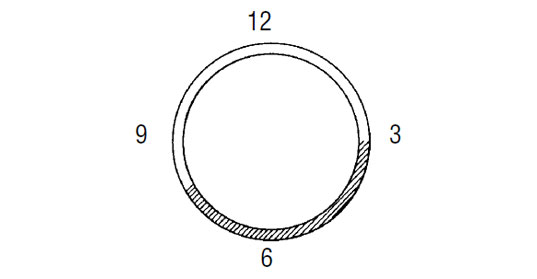

Veshin në përgjithësi do të gjendet nga 3:00 ora për të 8:00 Pozicioni ora.

Engine volant Strehimi Pilot

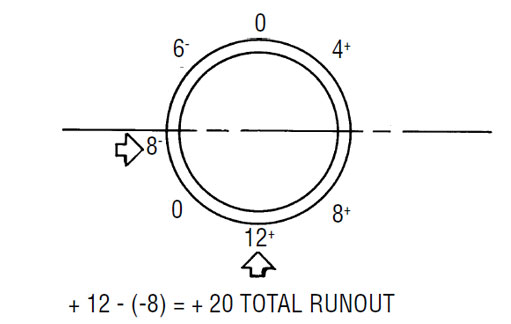

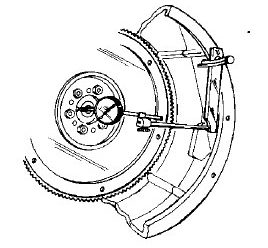

Telefononi tregoni pilotin ose pusin e strehimit të volantit të motorit. Tregues i sigurt i thirrjes në volantin e motorit me pikë konike kundër pilotit të strehimit. Rotate volant me dorë. Me shkumës ose gur sapuni, shënoni pikat e larta dhe të ulëta të treguesit ndërsa rrotullohet.

Shkarkimi i përgjithshëm do të jetë ndryshimi midis leximeve më të larta plus dhe minus. Mbërritja totale maksimale e SAE për pilotin e strehimit të volantit është .008″ me shtëpitë Nr.1 dhe Nr.2 SAE.

Volant Pilot Bore

Dial tregojnë pilot-duke mbajtur lindi e volant. Me tregues të siguruar në strehën e volantit, lëviz gishtin matës për të kontaktuar pilotin që mban sipërfaqen e mprehtë. Ktheni volantin dhe merrni lexime. Mbërritja totale maksimale e SAE për mbajtësin pilot është .005″.

Transmetimit anësor Strehimi

Fytyra dhe piloti i strehimit të tufës së transmisionit nuk mund të kontrollohen me saktësi në terren pa mjete të posaçme matëse. Shkarkimi maksimal i rekomanduar për fytyrën dhe pilotin e strehimit të tufës së transmisionit është .003″ me shtëpitë SAE Nr.1 dhe Nr.2.

ndonjë pjesa e transmetimit ju keni nevojë për ne kemi atë! Të njëjtën ditë të anijeve në dispozicion, botëror.

DUHET pa mbështetje nga një prej ekspertëve tanë?