Driveline Angularity ngungkulan

Torsional Geter

Mariksa Driveline U-Joint Operasi sudut

Peta ngeunaan driveline kalayan gabungan universal di boh tungtung digawé ngaliwatan hiji hasil sudut dina gerak aneh. driveline bakal nyepetkeun sarta ngalambatkeun turun dua kali pikeun tiap revolusi. Lamun sudut gawe di boh tungtung aci mangrupakeun unequal, Hasil Geter torsional. Geter torsional ieu bakal condong ngabolaykeun sorangan kaluar lamun duanana sudut digawé gabungan sarua.

Rupa Noise

Noise atanapi Geter nu lumangsung ngan dina speeds jalan tangtu jeung diminishes sakumaha speed nambahan sacara umum disababkeun ku sudut kerja unequal of mendi driveline. Noise atanapi Geter nu pengkuh sapanjang rentang speed na variasina dina inténsitas kalayan parobahan speed bisa jadi dibalukarkeun ku drivelines henteu saimbang, drum marake henteu saimbang atanapi cakram, atanapi drivelines kalawan mendi universal kaluar fase.

cék awal

Jieun cék sahiji handap saencan nyandak maca sudut:

- Check companion flange or yoke nut for looseness and torque to proper specification if necessary.

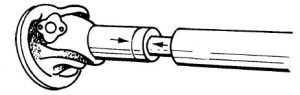

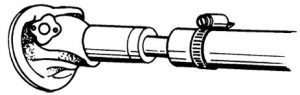

- Driveline slip joints that do not have the arrows or other markings pointing to each other will result in the driveline universal joints being out of phase. Istilah sanésna, the transmission universal joint may be turned one spline or more to the right or left of being aligned with the universal joint at the opposite end of the driveline.

- Some computer designed drivelines are purposely built with U-joints out of phase. Check manufacturer’s specifications for proper setting. oge, check closely to make certain no twist has occurred to the tubing, causing these two joints to be out of phase Make sure the slip joint works freely and is not bound or seized. Slip joints must absorb axle housing movements.

- Unbalanced drivelines can cause vibration that occurs throughout the speed range of vehicle and varies in intensity with a change of speed. The driveline may be at fault in respect to balance and concentricity. A quick field check to determine driveline balance can be made by securing a small piece of metal or similar weight with a hose clamp to the front of the tube where the splined shaft is welded. Road test the vehicle and continue to move the weight around the tube until the balance point is found and vibration disappears or is minimized.

Drivelines anu dinamis saimbang mun laju rotational maranéhna dimaksudkeun na teu speeds wates. kituna, vibration can be expected when this rotational velocity is exceeded. Check concentricity of driveline by mounting on lathe centers and dial indicating. Pariksa spésifikasi produsén urang keur sangu runout. - ngarojong engine nu dipaké, rusak atawa leupas, and mounting pads that are worn or deteriorated must be corrected to restore the engine suspension to its original vibration tolerance.

nyandak maca

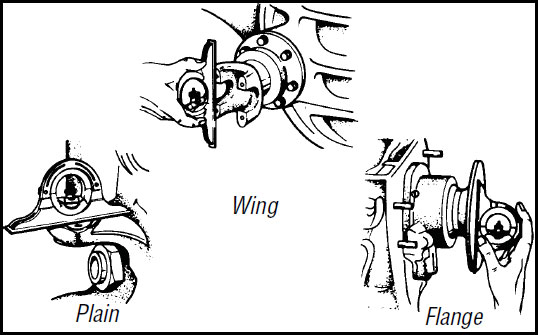

Take readings with protractor from machined surfaces of yokes or companion flanges. sederhana, jangjang atawa tipe flange mendi bisa jadi encountered. Some will require partial disassembly to obtain accurate readings.

Dina tipe mendi polos, it may be necessary to remove the bearing cap. Sawaktos nyandak maca, make sure the universal joint is in a vertical plane. At the rear axle, take readings from a machined surface differential carrier that is in the same plane as the axle pinion shaft, atanapi ti permukaan machined nu geus jejeg pinion aci, whichever téh gampang.

Mun Geter lumangsung bari operasi kosong, take readings in empty condition. Lamun lumangsung nalika dimuat, take readings when loaded. When it is necessary to measure driveline lengths, measure from joint center to joint center

spésifikasi produsén urang kudu dituturkeun nalika nyieun dipariksa angularity awal. Some manufacturers have found it necessary to vary from the ideal due to geometrical limitations. If vibration persists after adhering to manufacturer’s specifications, contact the manufacturer’s representative.

Cék Angularity - Flanges Parallel atanapi Yokes

- Kandaraan as hiji

- sudut transmisi – Take reading of transmission angle. This angle is the angle to which the rear axle joint angle must match. The transmission angle will have a declination reading of from 0 ka 5 derajat di hal nu ilahar.

- sudut as. Take reading either from machined surface of axle housing or pinion bearing retainer. This angle must be within one degree of the transmission angle.

- conto: If transmission angle reading is 3 degrees down to the rear, the rear axle angle should be 3 derajat up.

- sudut transmisi – Take reading of transmission angle. This angle is the angle to which the rear axle joint angle must match. The transmission angle will have a declination reading of from 0 ka 5 derajat di hal nu ilahar.

- Tandem Axles atanapi Kandaraan jeung Unit bantu

- Candak transmisi sudut bacaan.

- Take reading from joint of front tandem axle or auxiliary joint. This reading should be within one degree of transmission angle.

- Catetan: The rear joint of front tandem axle will be the same as the front joint.

- Candak bacaan tina sudut joint di tandem as pungkur, or axle to rear of auxiliary. This angle must be within one degree of transmission angle.

Gabungan wates ngagawekeun Angle (sajajar)

sendi Universal boga sudut kerja maksimum, gumantung kana jenis jeung pabrik. Eta Dianjurkeun yén sudut kerja gabungan keur assembly gabungan paralel moal ngaleuwihan 8 derajat pikeun drivelines utama leuwih 40″ panjang. Pikeun drivelines utama dina 40″ sudut maksimum teu kudu ngaleuwihan Panjang (L) dibagi ku 5. (wates ieu teu dilarapkeun ka interaxle drivelines.)

conto: Pikeun 35″ driveline, the maximum joint working angle would be 35 tambah 5 atanapi 7degrees. This working angle must not be exceeded.

Place protractor on driveline to obtain angle of driveline from transmission to axle. The difference between the driveline angle and the joint angle is the joint working angle. For instance, lamun transmisi anu mangrupa 3 derajat handap, and the driveline angle is down 7 derajat, the transmission joint working angle is 7 kirang 3 atawa 4 derajat.

Dina tandem drive atanapi pamasangan bantu, take readings in the same manner, comparing the universal joint angles to the driveline angle to which it is attached.

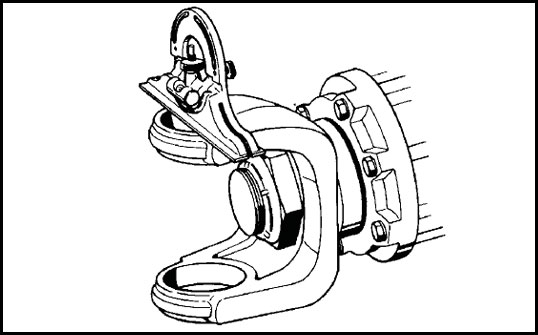

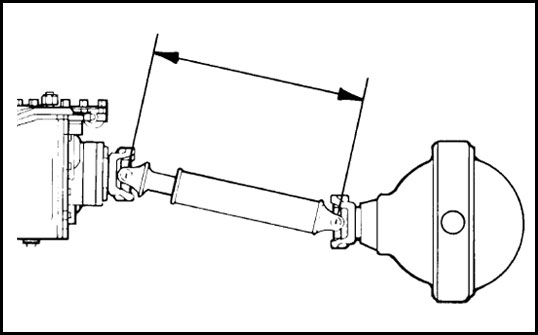

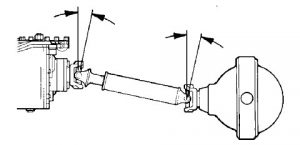

Angularity Checks – Non-Parallel Compensating Angles or Flanges or Yokes

Kalayan kandaraan basa kabayang pondok nu boga panjang driveline minimum tina transmisi nepi as, driveline anu diperlukeun pikeun beroperasi ngaliwatan sudut kerja pisan parna dina sababaraha pamasangan. Ieu ogé lumaku pikeun interaxle drivelines. Ieu parah kerja gabungan sudut dipicuna Geter. Ngurangan sudut bisa dipake, as kasebut tilted luhur dugi ka centerline pinion aci jeung transmisi mainshaft centerline motong midway antara puseur gabungan.

Kalawan axles tandem drive, the rearward axle is tilted upward until its pinion shaft centerline and forward axle pinion shaft centerline intersect midway between joint centers.

Nalika figuring pamasangan gabungan non-paralel, it is necessary to take the driveline angle readings as well as transmission and axle angle readings.

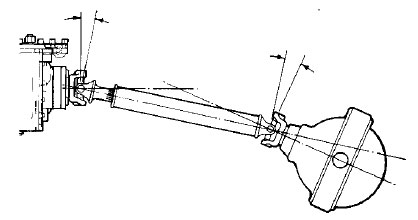

- Kandaraan as hiji

- Candak sudut bacaan transmisi

- Candak sudut driveline

- Candak sudut bacaan tina as gabungan

- Pikeun ngitung pikeun sudut bener:

- The difference between the driveline angle and the transmission angle will be the transmission joint working angle.

- The difference between the driveline angle and the axle angle will be the axle joint working angle.

- The two working angles of transmission and axle must be equal.

- conto:

transmisi anu 3 derajat handap

Driveline nyaeta 7.5 derajat handap

as pungkur nyaeta 12 derajat handap

kituna 7.5 kirang 3 sarua 4.5 derajat

12 kirang 7.5 sarua 4.5 derajat, giving 4.5 equal working angles

- Tandem Axles atanapi Kandaraan jeung Unit bantu – When taking readings on tandem drive axles or between auxiliary and rear axle, the same principles apply as with single axle vehicles. Take readings between transmission and front tandem axle, or auxiliary. Take readings between axles or between auxiliary and axle. Istilah sanésna, take angle readings for each set of universal joints

Gabungan wates ngagawekeun Angle (Non-Parallel)

Eta Dianjurkeun yén sudut kerja gabungan maksimum pikeun majelis gabungan non-paralel moal ngaleuwihan panjangna driveline utama dibagi 10. Salaku conto, lamun éta panjangna driveline utama 55, sudut gabungan kerja maksimum nyaéta 55 dibagi ku 10 atawa 5.5 derajat. (wates ieu teu dilarapkeun ka interaxle drivelines.)

pangaluyuan as

sudut as bisa umum disaluyukeun ku salah sahiji cara di handap ieu, gumantung kana jenis tina as.

- Saluyukeun torsi rod, lamun jenis adjustable.

- Add to or reduce length of non-adjustable torque rods.

- Add or reduce the number of shims behind torque rod brackets.

- Use correct amount of wedge shims under spring to axle pad.

Suspensions - Pinion aci Angle

Bakal aya saeutik atawa teu robah tina sudut pinion as kalawan rupa suspensions nu boga gerakan parallelogram. Ieu ngidinan housings diferensial pindah luhur jeung ka handap dina nangtung lempeng mangsa operasi.

Suspensions teu gaduh gerak parallelogram bakal ngidinan aci as pinion mun oscillate dina arc, kukituna terus ngarobah sudut aci pinion mangsa operasi. A Jumlah varying of Geter bisa lumangsung disababkeun ku sudut gawé ti mendi universal keur momentarily unequal.

Hiji drive kandaraan as gaduh sakedik atanapi henteu robah tina sudut as pinion mangsa operasi.

sagala bagian transmisi anjeun peryogi urang gaduh eta! pengiriman barang dinten anu sami sadia, di sakuliah dunya.

Kudu ngarojong FREE ti salah sahiji ahli kami?