Solução de problemas de alinhamento de transmissão Eaton Fuller

Alinhamento concêntrico de Transmissão de motor

Preocupações ordinárias resultantes da Desalinhamento

slipout engrenagem direta

Falha no rolamento da engrenagem motriz

desgaste prematuro de entrada eixo da ranhura de cubo traseiro de duas garras de placas

alinhamento concêntrico

O alinhamento concêntrico significa que o motor e a transmissão devem ter um eixo comum. O objetivo desta seção é estabelecer os procedimentos a serem usados na verificação de possível desalinhamento.

O instrumento básico necessário para fazer leituras é um relógio comparador de ponta cônica. A precisão das leituras é essencial para corrigir problemas de alinhamento. Limpe todas as superfícies completamente antes de prosseguir.

Ao tomar as seguintes leituras, gire motor à mão, não dê partida no motor com partida. Remova as velas de ignição dos motores a gasolina, e liberar compressão em motores diesel.

Nota: Antes do mostrador indicando o volante do motor ou a carcaça do volante, certifique-se de que o virabrequim do motor não tenha folga excessiva. Se isso acontecer, leituras precisas não podem ser obtidas. Coloque o dedo indicador do mostrador contra o volante. Forçar o virabrequim para frente e para trás com alavanca. Se o movimento da folga exceder o máximo especificado pelo fabricante do motor, ele terá que ser corrigido.

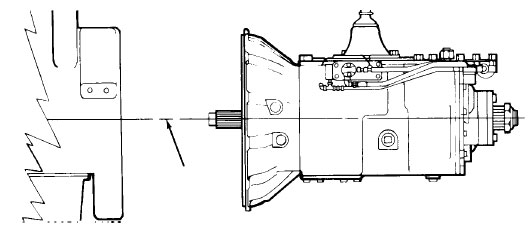

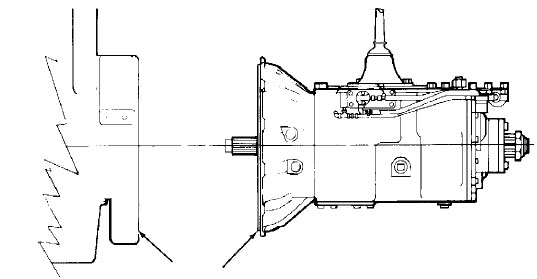

Carcaças desgastadas

Inspecione se há piloto desgastado ou desgastado na carcaça da embreagem da transmissão e na carcaça do volante do motor. o 1/4″ a borda piloto da carcaça da embreagem da transmissão pode desgastar a carcaça do volante, seja pelo afrouxamento da transmissão ou após uma alta quilometragem apenas devido à vibração da estrada e do motor.

Qualquer quantidade apreciável de desgaste em qualquer uma das peças causará desalinhamento e a peça deverá ser substituída.

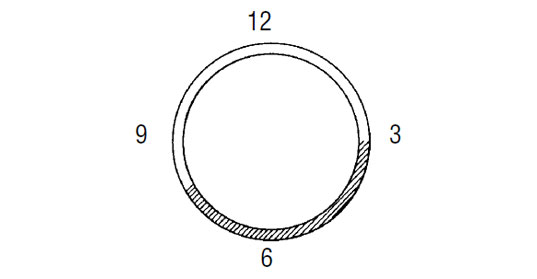

O desgaste geralmente ser encontrada a partir da 3:00 horas para 8:00 horas posição.

Motor carcaça do volante Pilot

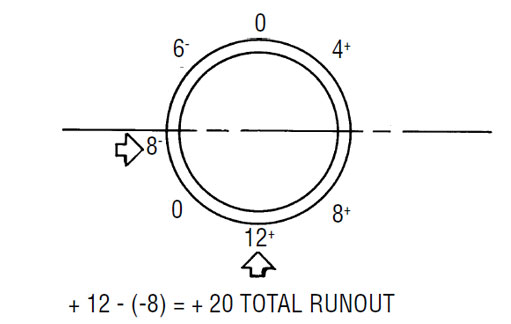

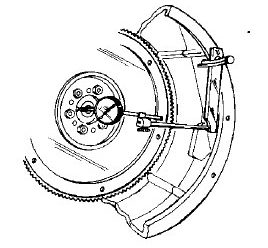

O mostrador indica o piloto ou furo da carcaça do volante do motor. Fixe o relógio comparador ao volante do motor com ponta cônica contra o alojamento do piloto. Gire o volante com a mão. Com giz ou pedra-sabão, marque os pontos altos e baixos do indicador enquanto ele está sendo girado.

O desvio total será a diferença entre as leituras mais altas e negativas. O desvio total máximo SAE para o piloto da carcaça do volante é .008″ com alojamentos SAE No.1 e No.2.

Orifício do volante Pilot

Dial indicam furo piloto do rolamento de roda volante. Com indicador preso à carcaça do volante, mova o dedo do medidor para entrar em contato com a superfície do furo do rolamento piloto. Gire o volante e obtenha leituras. O desvio total máximo SAE para o rolamento piloto é .005″.

Transmissão Clutch Housing

A face da carcaça da embreagem da transmissão e o piloto não podem ser verificados com precisão em campo sem ferramentas de medição especiais. O desvio máximo recomendado para a face da carcaça da embreagem da transmissão e o piloto é .003″ com alojamentos SAE No.1 e No.2.

Qualquer parte de transmissão você precisa temos que! O mesmo transporte do dia disponível, no mundo todo.

Precisam de apoio gratuito de um de nossos especialistas?