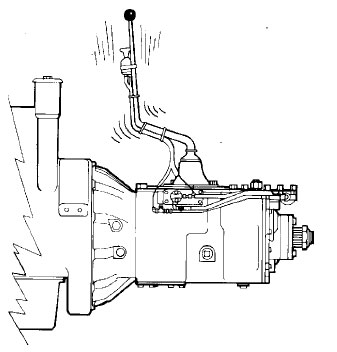

Eaton Fuller prijenosa rešavanje problema

Guide to servicing and repairing Eaton Fuller heavy-duty truck transmission, pomoć oko pronalaženja pitanje prenošenja problema, analyze the cause and make necessary repairs for 7, 8, 9, 10, 13, 15 i 18 ubrzati Eaton transmisije. For more in-depth assistance refer to your transmission model service manual or give us a call at 877-776-4600. Funkcija prenos je da efikasno prenijeti snagu motora, u smislu momenta, na zadnje točkove vozila. Moment je uvijanje ili kružnim snagu isporučuje zamašnjak motora. prenosnim odnosima menjača povećati ili smanjiti moment ovisno o zahtjevima potrebno za pomicanje ili pokretanje opterećenje. Prijenosnih povećava ili smanjuje brzinu. Prenosnih odnosa pravilno raspoređene tako da će motor raditi u svom najefikasniji domet RPM sa progresivnim promjenama brzine. Da bi se ispunili zahtjevi vozila, prijenos mora imati omjer dovoljno niska za pokretanje vozila u pokretu, da se održi kretanje gore-razreda, i da bi motor radi u svom asortimanu vrhuncu efikasnosti. prijenos, također, moraju pružiti jednostavan način za biranje brzina.

Vodič za sljedeće prijenos modelima Eaton Fuller:

Common prijenosa žalbe

vibracija

Although the effects of vibration will show up in the transmission, vibration usually originates somewhere else in the drive train. Vibration can usually be felt or heard by the driver; kako god, u nekim slučajevima, transmission damage caused by vibration will occur without the driver’s knowledge.

Neki prijenosa problemima zbog pogonskog vibracija:

- Gear zvečka u stanju mirovanja

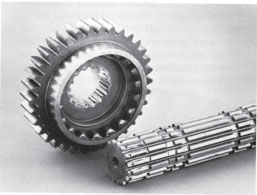

- zupčanik & shaft splines (zareža)

- buka

- zareža ležajevi

- Ponovljeno pečat curenja zadnje

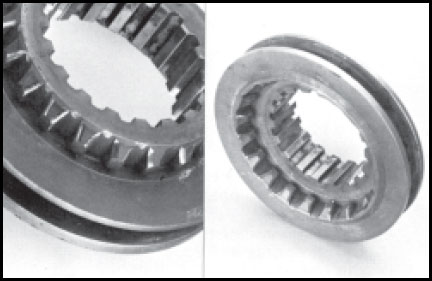

- Broken ili labave sinhronizator igle

- Kontinuirano labavljenje capscrews, konzole i nosači

- Istrošeni Shaft Spine Wear

- Worn universal joints (Nije prijenos simptom, ali indikator vibracija.)

zareža Splines

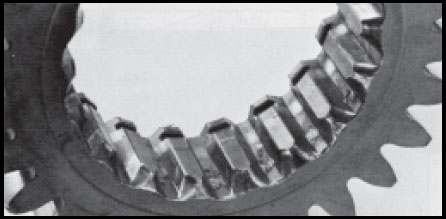

Broken Synchronizer Igle

Ulaz Spline Wear

Common causes of vibration include driveline imbalance or misalignment, neuravnotežen točkovima ili doboša, grubo rad motora, slomljena ili izlizanog nosači motora i istrošene suspenzija.

Gear Slipout i Jumpout

prednji dio

Kada je klizna kvačilo preselio da se uključe sa MAINSHAFT brzinu, zubi parenja mora biti paralelan. Sužava ili nositi držeći zubi će pokušati da "hoda", osim što je brzina rotirati. Pod pravim uslovima, slipout će rezultirati. Neki od ovih uvjeta su:

- Prenos montiran ekscentrično sa zamašnjaka motora pilot.

- Prekomjerne zupčanik sukobljenih što skraćuje pedale kvačila zuba.

- Nepravilno podešavanje daljinskog smjene kontrole povezanosti što rezultira parcijalne angažman. Također provjerite za labave veze i istrošene čaure.

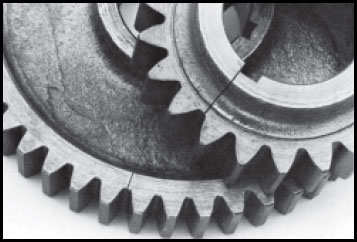

Otresao držeći Teeth

Gear stežući zube nosi na konus.

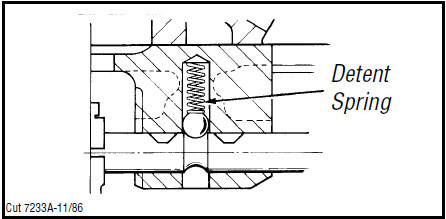

Razdjelni Spring

Nedovoljna pritisak na zadržavanja lopte iz slabi ili slomljen Zapirač proljeće.

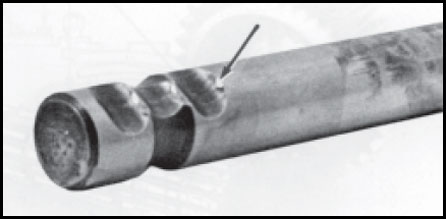

Istrošen Yoke Bar

Izlizan na Zapirač zarez jaram bar

Uvjete koji mogu izazvati Jumpout

- Ekstra teške i duge smjene poluge koji swing, klatno fashion, iz poslovnih preko neravnog terena. Mućenje djelovanja poluge prevazilazi Zapirač opruzi.

- Mehanički daljinski upravljači sa glavnim montiran na okvir. Relativna kretanja između motor-prijenos paketa i okvir može prisiliti prijenos iz brzine. Istrošeni ili slomljeni nosači motora povećati efekte ovog stanja.

Pomoćni točki

Slipout in the auxiliary section may be caused by the clutching teeth being worn, sužava, ili ne u potpunosti uključen. These conditions cause the clutch gear to “walk” out of engagement as the gears turn.

Causes of these types of clutching defects are clashing or normal wear after long life. Vibrations set up by an improperly aligned driveline and low air pressure add to the slipout problem.

Jumpout in the auxiliary section usually occurs with the splitter gear set. If torque is not sufficiently broken during splitter shifts, the sliding clutch gear may not have enough time to complete the shift before torque is reapplied to the gears. Kao moment se ponoviti, the partially engaged clutch gear “jumps” out of the splitter gear. Since the gears have torque applied to them, damage will be done to the clutching teeth of the mating gears.

hard Shifting

The effort required to move a gear shift lever from one gear position to another varies. If too great an effort is required it will be a constant cause of complaint from the driver.

Većina pritužbi su tipa daljinski veze koriste u vozilima bez kabine motora. Before checking the transmission for hard shifting the remote linkage should be inspected. Linkage problems stem from worn connections or bushings, vezivanje, improper adjustment, lack of lubrication on the joints or an obstruction which restricts free movement. Kako bi se utvrdilo da li je sama prijenos je uzrok teško prebacivanje, uklonite ručice mjenjača ili povezanost sa vrha prijenos. onda, move the shift blocks into each gear position using a pry bar or screwdriver. If the yoke bars slide easily, problem je sa Skupštinom povezivanje. If the trouble is in the transmission, it will generally be caused by one of the following:

- Splines of sliding clutch gear binding on mainshaft as a result of a twisted mainshaft key, bent shift yoke or bowed mainshaft key.

- Jaram barova obavezujuće u kućištu baru kao rezultat napukla stanovanja, preko Stegnuto pomak blok lockscrew, sprung yoke bar, or swelled areas of the yoke bar.

Ako dođe do teško prebacivanje samo u prvoj i obrnuto, the shift block detent plunger movement may be restricted. This can result from burrs on the plunger, or from overtightening the plunger spring plug. With the plunger blocked in the depressed position, the plug should be tightened until it bottoms out against the spring, onda odustao 1/4 u 1/2 zaokret.

Gear sukobljenih ne treba miješati sa čvrstim prebacivanje. Gear clashing occurs when an attempt is made to engage the clutch gear before it has reached synchronization with the mainshaft gear.

vrućina

The transmission operating temperature should never exceed 250°F (120° C) na duži vremenski period. Ako se to desi, the oil will breakdown and shorten transmission life.

Zbog trenja pokretnih dijelova, transmissions will produce a certain amount of heat. In most cases normal operating temperature is approximately 100°F (40° C) above ambient. Heat is dissipated through the transmission case. When conditions prevent the proper dissipation of heat, then overheating occurs.

Prije provjere mogućih uzroka pregrijavanja, the oil temperature gauge and sending unit should be inspected to make sure they are giving correct readings.

Causes of Overheating

1. Nepravilno podmazivanje. nivo ulja prenizak ili previsok, wrong type of oil, or an operating angle of more than 12 stupnjeva.

2. Rade dosljedno 20 MPH.

3. Visoke motor RPM.

4. Ograničen protok zraka oko mjenjača, due to the transmission being “boxed in” by frame rails, deck lids, rezervoari za gorivo i nosače, or by a large bumper assembly.

5. Izduvni sistem preblizu prijenos.

6. Visoka temperatura.

7. Velika snaga, overdrive rad.

8. Kotrljanje nizbrdo sa kvačila pritisnuta.

U nekim slučajevima, an external oil cooler kit can be used to correct overheating problems.

Prenos hladnjaka ulja su:

preporučuje se

- Sa motorima od 350 H.P. and above with overdrive transmissions

potreban

- sa motorima 399 H.P i gore sa overdrive

transmisije i GCWs preko 90,000 lbs. - sa motorima 399 H.P. i iznad i 1400 Lbs.-Ft.

ili veći okretni moment - sa motorima 450 H.P. i gore

Prenos buke

There will always be a certain level of noise due to the normal transmission operation. kako god, excessive noise or unusual noise such as a whine, režanje, or squeal indicates some kind of a problem.

The transmission itself can be the cause of excessive or unusual noise. takođe, noise can originate elsewhere in the vehicle, ali se pokupio i pojačava prijenos.

1. Knocking ili Thudding

- Gears - Bumps ili bubri na brzinu zubima. Such bumps or swells can be removed with a hone or small hand grinder; these areas can be identified as highly polished pots on the face of the gear tooth. obično, this noise is more prominent when the gear is loaded; tako, the problem gear can be located as the noise occurs in a specific gear position. Bumps or swells are caused by improper handling of gears before or during assembly.

- ležajevi – Noise comes in at low shaft speeds in any position. It is caused by bearings with damaged balls or rollers, or with pitted and spalled raceways.

- Cracked Gear – A gear cracked or broken by shock loading or by pressing on shaft during installation will produce this sound at low speeds. Pri visokim brzinama urlik će biti prisutan.

2. High Pitched Whine or Squeal

- Gear Wear - Rezultat normalnog trošenja zupčanika, including gear tooth pitting from excessive use. In advanced deterioration, urlik će rezultirati.

- Mismatched Gear Sets – Such gear sets are identified by an uneven wear pattern on the face of gear teeth.

- Ležajevi - "zapinje" ležajevi, having insufficient axial or radial clearance

3. brunda

- Timing Error – Improper timing of the transmission during reassembly, or improper timing due to gear turning on the countershaft. Both conditions produce an error in tooth spacing.

Causes of Transmission Noise Originating Elsewhere in Vehicle:

- Rough praznom hodu motor. (pogledajte gear zvečka)

- Motor buke.

- Clutch driven plates in which the dampening action of springs or rubber blocks has been eliminated by wear set or fracture.

- Pogonski sklop iz ravnoteže.

- Nejednakih zajednički rad uglova.

- Nositi križevi u zglobovima.

- Labave ili izlizanog centar ležajevi.

- Istrošeni ili koštice zubi na prsten zupčanika i zupčanik od pogonska osovina.

- Stražnja osovina neuspjeh ležaj.

- Wheels iz ravnoteže.

- Istrošene proljeće pivot ležaj.

- Loose "U" vijaka.

- Kočnice bubnjevi izobličenja ili iz ravnoteže.

Prenos rješavanje problema je Smjernica

Following is a basic procedure guideline for troubleshooting transmissions:

- preliminarni pregled

- lično zapažanje – look for signs of misuse such as broken mounts, pribor ili zagradama; check airlines.

- Pitanje vlasnika ili operatora – gather information on operating conditions and vehicle use, o povijesti problema, and on shifting characteristics if affected.

- Okupiti Istorija jedinice – including maintenance and lubrication procedures, prošlosti kvarova, i kilometraža ili sati korištenja.

- Skinite prijenosa

- Držite uzorak ulje za nečistoće, provjeriti ako je to potrebno.

- tokom demontaža, check for incorrectly installed parts, nedostajućih dijelova, and nongenuine parts.

- Očistite i pregledajte svaki komad pažljivo.

- Odrediti Vrsta Failure

- Odrediti i ispraviti uzrok neuspjeha

The Troubleshooter’s Guideline Chart is used to locate and correct transmission problems. To use the guideline,

1) Locirati problem prenosa u polja ispod

2) Hover over the box to see the possible problem and take note of the numbers next to the possible cause

3) Pogledajte listu ispod i pronađite odgovarajući broj naveden pored problema. Broj usklađivanje sa liste će vam reći da je moguće korekcije.

4) Može biti više od jednog od mogućih uzroka i mogućih korekcija za svaki problem.

eventualne korekcije:

- Uputiti vozača pravilne tehnike vožnje.

- zamijeniti dijelove (after trying other listed possible corrections).

- Otpustite lock-vijak i zategnite na odgovarajući moment.

- Potražite rezultanta štete.

- Glatka sa šmirgl papir.

- Reset to ispravno navedene.

- Instalirati nedostaju dijelovi.

- Provjerite airlines ili crijeva.

- zategnite deo.

- Ispravite ograničenje.

- Ponovo provjeri timing.

- čistom delu.

- Nanesite tanki sloj silikona.

- Nanesite brtvilo.

bilo koji prijenos dijela trebate ga imamo! Isti dan shipping dostupni, svjetski.

TREBA Besplatna podrška od jednog od naših stručnjaka?