Feilsøking Eaton Transmisjon Gears & aksler

kranglet Gears

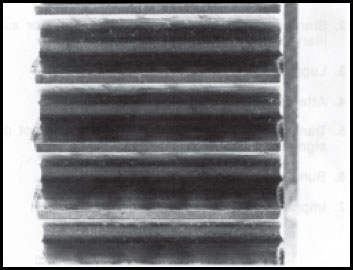

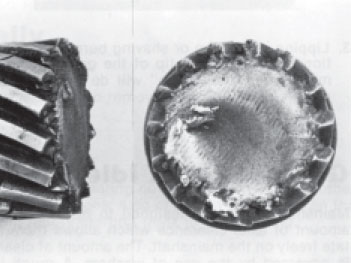

Snubbing and clashing gears while shifting are frequent abuses to which unsynchronized transmissions are subjected. Light snubbing will do little damage. The real damage is done by the hard clash shift caused by engaging gears which are far out of synchronization. This can break pieces of metal from the ends of the clutching teeth. Clashing gears can be traced to one of three causes:

Avvist tviholdt Gear Teeth

1. feilaktig Shifting

This applies to drivers who are not familiar with the shift pattern or have not learned the RPM spread between shifts.

2. Kløtsj

Clashing when starting up in first or reverse gear can be caused by insufficient clutch clearance or a dragging clutch not releasing properly. This makes the transmission countershafts and mainshaft gears continue rotating while the clutch pedal is depressed. Clashing results when the nonrotating sliding clutch is forced to mesh with a rotating mainshaft gear. Double clutching during lever shifts will also reduce snubbing and clashing.

3. treghet Force

Countershafts og mainshaft tannhjul vanligvis tar fra 3 til 5 sekunder for å slutte å rotere etter at clutchen er koblet. Forsøk på å mesh en clutch tannhjul med et tannhjul mainshaft før den mainshaft utstyret stopper vil resultere i butt. Hvis overføringen ikke er utstyrt med en clutch brems eller mellomakselbremse, det er nødvendig å stanse et par sekunder etter kløtsjpedalen før prøver første inngrep av overførings.

produksjons~~POS=TRUNC Marks

Sometimes gears are replaced or thought to be defective because of marks left on the gear by manufacturing processes. disse blemishes, derimot, do not contribute to gear failure and the gear should not be replaced because of these marks.

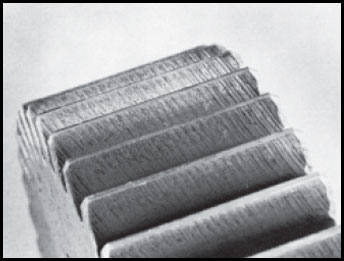

Hob Marks

These are cutting marks or lines formed during the initial cutting of the gear teeth. Hob marks on the tooth face will be removed by the shaving process, but hob marks in the root of the tooth will most likely remain, and may be found even on gears with much wear on them.

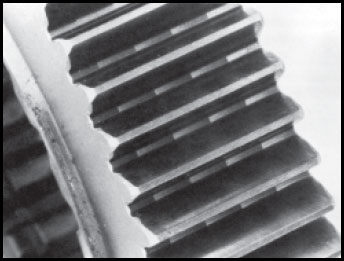

barbering Marks

The shaving operation leaves distinct diagonal marks on the face of the gear tooth. These marks can be distinguished from scoring marks by the fact they are diagonal, while scoring marks are more nearly vertical. Most shaving marks are removed during normal gear operation.

Gear Rattle ved tomgangs

Mainshaft gears are designed to have a specified amount of axial clearance which allows them to rotate freely on the mainshaft. The amount of clearance is governed by the use of washers. En ujevn tomgang motoren kan sette opp vibrasjoner, causing the mainshaft gears to rattle as they strike mating gears. This condition can usually be cured by improving the idling characteristics of the engine. Tolerance washers may have to be changed to bring the axial gear clearance to within tolerance on high mileage units. See the service manual for procedure and specifications.

Shaft Twist og Fracture

Failure of transmission shafts through fracturing or twisting is caused when stresses are imposed on them which are greater than they were designed to withstand. The main causes for these failures are:

- Feilaktig tviholdt teknikker.

- Fra og med altfor høyt av utstyr.

- lugging.

- Forsøk på å starte med bremser låste.

- Transmission used for application it was not designed to withstand.

- Borti dokken ved rygging.

- Feilaktig montering av innstillbar femte hjul.

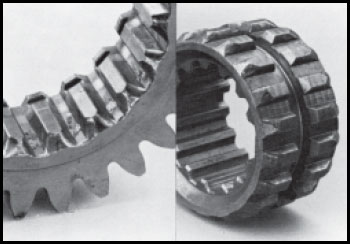

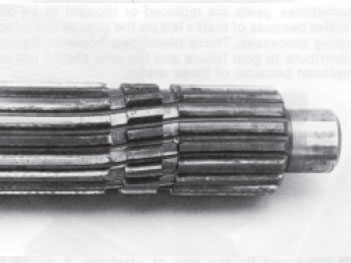

Fractured Mainshaft

Som med tannhjulstenner, shafts may fracture as a result of fatigue or impact.

Twisted Mainshaft

Loads not severe enough to cause shaft fractures may cause the shaft to twist.

Noen senderdel du må vi ha det! Samme dag shipping tilgjengelig, verdensomspennende.

Trenger gratis støtte fra en av våre eksperter?