Eaton Fuller Transmission Alignment Troubleshooting

Konsentrisk innretting av Transmission til Engine

Felles bekymringer som følge av skjevt

Direkte utstyr slipout

Drive gear bearing failure

Prematur inngående aksel spline slitasje fra baksiden av navet to lamellclutchene

konsentrisk innretting

Concentric alignment means that the engine and transmission must have a common axis. The purpose of this section is to set forth the procedures to use in checking for possible misalignment.

The basic instrument needed for taking readings is a taper pointed dial indicator. The accuracy of readings is essential for correcting alignment problems. Clean all surfaces thoroughly before proceeding.

Når du tar disse målingene, rotere motoren for hånd, do not crank the engine with starter. Remove spark plugs on gasoline engines, and release compression on diesel engines.

Merk: Before dial indicating engine flywheel or flywheel housing, make sure engine crankshaft does not have excessive end-play. Hvis den gjør det, accurate readings cannot be obtained. Place dial indicator finger against the flywheel. Force crankshaft back and forth with pry bar. If end-play movement exceeds maximum as specified by the engine manufacturer, det må korrigeres.

slitte Housings

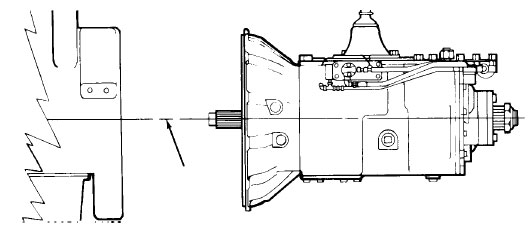

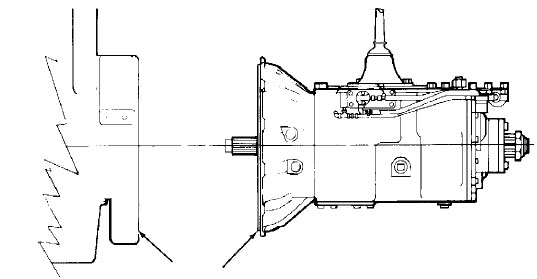

Inspect for worn or fretted pilot on both the transmission clutch housing and the engine flywheel housing. 1/4″ pilot lip of transmission clutch housing can wear into the flywheel housing either by transmission loosening up or after high mileage just from the road and engine vibration.

Any appreciable amount of wear on either part will cause misalignment and the part should be replaced.

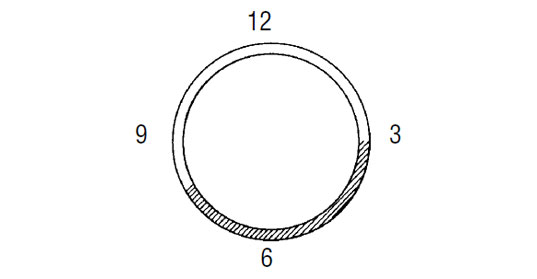

Slitasjen vil generelt bli funnet fra 3:00 klokken til 8:00 seks posisjon.

Motor Svinghjulhus Pilot

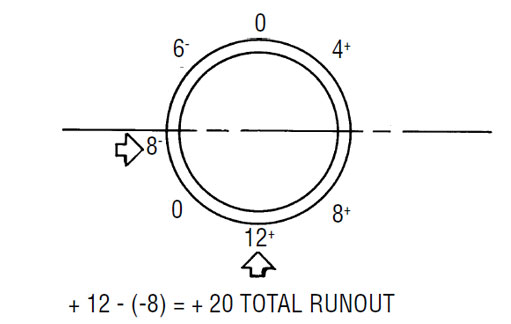

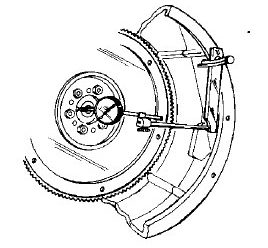

Dial indicate the pilot or bore of the engine flywheel housing. Secure dial indicator to engine flywheel with tapered point against housing pilot. Roter svinghjulet manuelt. With chalk or soapstone, mark high and low points of indicator as it is being rotated.

The total runout will be the difference between the highest plus and minus readings. SAE maximum total runout for flywheel housing pilot is .008″ with No.1 and No.2 SAE housings.

Svinghjul Pilot Bore

Dial indikere pilot lagerboringen svinghjul. With indicator secured to flywheel housing, move gauge finger to contact pilot bearing bore surface. Turn flywheel and obtain readings. SAE maximum total runout for the pilot bearing is .005″.

Overføring Clutch Housing

The transmission clutch housing face and pilot cannot be checked accurately in the field without special measuring tools. Recommended maximum runout for the transmission clutch housing face and pilot is .003″ with SAE No.1 and No.2 housings.

Noen senderdel du må vi ha det! Samme dag shipping tilgjengelig, verdensomspennende.

Trenger gratis støtte fra en av våre eksperter?