Problemen oplossen Eaton Transmission Gears & assen

botsende Gears

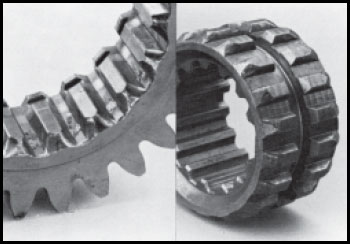

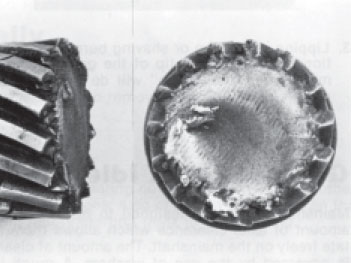

Het botsen en botsen van versnellingen tijdens het schakelen zijn frequente misstanden waaraan niet-gesynchroniseerde transmissies worden blootgesteld. Een lichte stoot zal weinig schade aanrichten. De echte schade wordt veroorzaakt door de harde clash shift die wordt veroorzaakt door het inschakelen van versnellingen die ver uit synchronisatie zijn. Hierdoor kunnen stukjes metaal van de uiteinden van de grijptanden breken. Botsende tandwielen kunnen worden herleid tot een van de volgende drie oorzaken:

Afgesnauwd Clutching Gear Tanden

1. Onjuiste Shifting

Dit geldt voor chauffeurs die niet bekend zijn met het schakelpatroon of de toerentalspreiding tussen diensten niet hebben geleerd.

2. Koppeling

Botsingen bij het starten in de eerste versnelling of de achteruitversnelling kunnen worden veroorzaakt door onvoldoende koppelingsspeling of een slippende koppeling die niet goed loskomt. Hierdoor blijven de secundaire assen en de hoofdastandwielen van de transmissie draaien terwijl het koppelingspedaal wordt ingetrapt. Botsingen ontstaan wanneer de niet-roterende glijdende koppeling gedwongen wordt in aangrijping te komen met een roterend hoofdastandwiel. Dubbele koppeling tijdens het schakelen tussen de hendels vermindert ook het botsen en botsen.

3. traagheidskracht

Contra-en hoofdas tandwielen Meestal nemen van 3 naar 5 seconden stilstaan nadat de koppeling is ontkoppeld. Probeert een koppeltandwiel samenwerken met een hoofdas tandwiel voor de hoofdas tandwiel stopt leidt tot botsende. Als de verzending niet is voorzien van een rem of koppeling tussenas brake, is het noodzakelijk om een paar seconden te wachten na het indrukken van het koppelingspedaal voordat het begin van aangrijpen van de transmissie.

Manufacturing Marks

Soms worden tandwielen vervangen of wordt aangenomen dat ze defect zijn vanwege sporen die tijdens productieprocessen op de tandwielen zijn achtergelaten. deze vlekken, echter, dragen niet bij aan het falen van de versnelling en de versnelling mag niet worden vervangen vanwege deze markeringen.

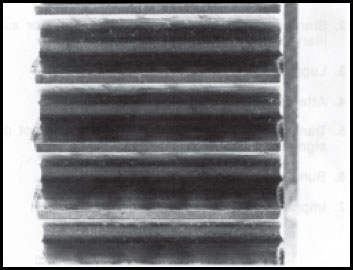

Hob Marks

Dit zijn snijsporen of lijnen die worden gevormd tijdens het eerste snijden van de tandwieltanden. Kookplaten op het tandvlak worden door het scheerproces verwijderd, maar kookplaatsporen in de wortel van de tand zullen hoogstwaarschijnlijk achterblijven, en kan zelfs worden aangetroffen op tandwielen met veel slijtage.

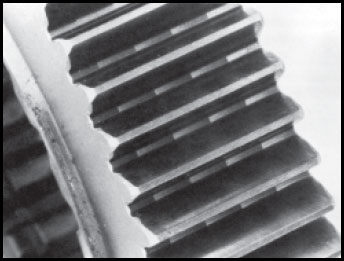

scheren Marks

Het scheren laat duidelijke diagonale markeringen achter op de voorkant van de tandwieltand. Deze markeringen kunnen worden onderscheiden van scoremarkeringen doordat ze diagonaal zijn, terwijl de scoremarkeringen bijna verticaal zijn. De meeste scheersporen worden verwijderd tijdens normaal gebruik van de versnelling.

Gear Rattle bij Idle

Hoofdastandwielen zijn ontworpen met een bepaalde hoeveelheid axiale speling, waardoor ze vrij op de hoofdas kunnen draaien. De hoeveelheid speling wordt bepaald door het gebruik van ringen. Een ruwe stationair draaiende motor kan het opzetten van trillingen, waardoor de hoofdastandwielen gaan rammelen als ze tegen elkaar passende tandwielen raken. Deze aandoening kan meestal worden verholpen door de stationairloopeigenschappen van de motor te verbeteren. Tolerantieringen moeten mogelijk worden vervangen om de axiale tandwielspeling binnen de tolerantie te brengen bij eenheden met een hoge kilometerstand. Zie de servicehandleiding voor procedure en specificaties.

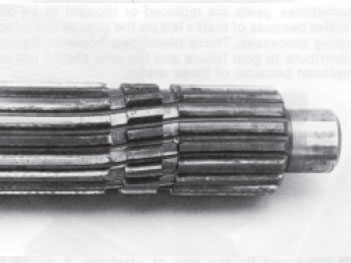

Shaft Twist and Fracture

Het falen van transmissieassen door breuk of torsie wordt veroorzaakt wanneer er spanningen op worden uitgeoefend die groter zijn dan waarvoor ze ontworpen waren.. De belangrijkste oorzaken van deze mislukkingen zijn:

- Onjuiste geklemd technieken.

- Beginnend in een te hoge versnelling.

- zeulen.

- Proberen om te beginnen met remmen geblokkeerd.

- Transmissie gebruikt voor toepassingen waarvoor deze niet ontworpen is.

- Stoten in dock tijdens het achteruitrijden.

- Verkeerde montage instelbare 5 wheel.

Fractured hoofdas

Zoals met tandwieltanden, schachten kunnen breken als gevolg van vermoeidheid of stoten.

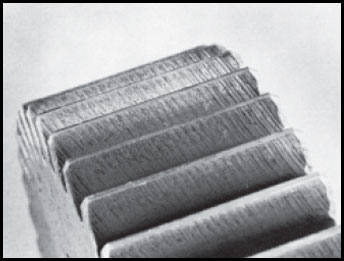

Twisted hoofdas

Belastingen die niet zwaar genoeg zijn om schachtbreuken te veroorzaken, kunnen ertoe leiden dat de schacht gaat draaien.

Ieder overbrengingsdeel je nodig hebt we het hebben! Dezelfde dag de scheepvaart beschikbaar, wereldwijd.

Vrij moeten steun van één van onze experts?