Leqa ni Angularity ni driveline

Torsional na sautaninini

Jeke na Driveline na veisele iko-yava musu

Na cakacaka ni dua na driveline vata kei na dua na yava ni vuravura raraba ena e dua vei rau na cakacaka ni oti mai e dua na kala ena kauta mai e dua na toso matalia. Ena totolo na toso na driveline kei na berabera vakarua me baleta yadua na cowiri. Kevaka sa sega ni ganita na musu ni taurivaki e dua vei rau sa tini na moto, macala ni sautaninini torsional. Oqo na sautaninini torsional na via bokoca vakaikoya kevaka era tautauvata na ruarua na musu cokovata ni cakacaka.

Na mataqali ni rorogo

Na rorogo se na sautaninini ka yaco ga ena kena gaunisala sa na totolo sara kei era na vakarusa laivi me vaka ena vakatubura na totolo e vakararaba ni vu mai na sega ni ganita na musu ni cakacaka na isema ni driveline. Rorogo se sautaninini na cikecike taucoko na ituvatuva ni totolo ka duidui tosocake vata kei na veisau ni totolo e rawa me vu mai na kena na drivelines, kena dovia caka se na Disi, se na drivelines vata kei ira na isema ni vuravura raraba mai na veituvatuva.

Tudei na jeke

Cakava na jeke na ka oqo ni bera ni vakacurumi na kala ni wiliwili ena veivuli:

- Check companion flange or yoke nut for looseness and torque to proper specification if necessary.

- Driveline slip joints that do not have the arrows or other markings pointing to each other will result in the driveline universal joints being out of phase. Ena dua tale na kena vosa, the transmission universal joint may be turned one spline or more to the right or left of being aligned with the universal joint at the opposite end of the driveline.

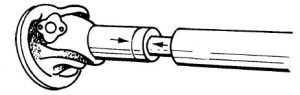

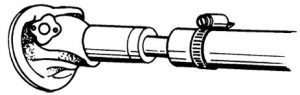

- Some computer designed drivelines are purposely built with U-joints out of phase. Check manufacturer’s specifications for proper setting. Talega, check closely to make certain no twist has occurred to the tubing, causing these two joints to be out of phase Make sure the slip joint works freely and is not bound or seized. Slip joints must absorb axle housing movements.

- Unbalanced drivelines can cause vibration that occurs throughout the speed range of vehicle and varies in intensity with a change of speed. The driveline may be at fault in respect to balance and concentricity. A quick field check to determine driveline balance can be made by securing a small piece of metal or similar weight with a hose clamp to the front of the tube where the splined shaft is welded. Road test the vehicle and continue to move the weight around the tube until the balance point is found and vibration disappears or is minimized.

Drivelines sa dynamically dau veidutaitaki beka ki na nodra inaki taukena na rotational kaukauwa dina sara ka kakua ni sega ni vakaiyalayala na totolo. Sa, vibration can be expected when this rotational velocity is exceeded. Check concentricity of driveline by mounting on lathe centers and dial indicating. Dikeva na itaratara ni nona siqeleti me baleta na tuvanaki ni runout. - Veitokoni ni idini ka e daramaki, sa kavoro se sereka, and mounting pads that are worn or deteriorated must be corrected to restore the engine suspension to its original vibration tolerance.

Tauri ni wiliwili ena veivuli

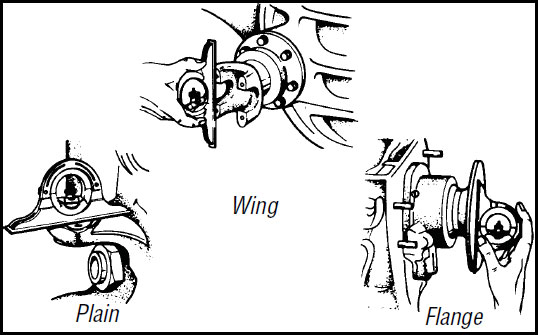

Take readings with protractor from machined surfaces of yokes or companion flanges. Rawarawa, e rawa ni sotavi na veisema ni tabana se na flange na mataqali. Some will require partial disassembly to obtain accurate readings.

Ena rawarawa na mataqali veisema, it may be necessary to remove the bearing cap. Ni taura ni wiliwili ena veivuli, make sure the universal joint is in a vertical plane. At the rear axle, take readings from a machined surface differential carrier that is in the same plane as the axle pinion shaft, se mai na dela ni machined ni perpendicular ki na moto ni pinion, e rawarawa cake na vakomipiuta.

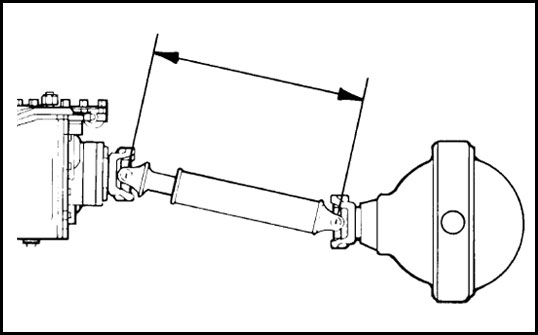

Kevaka e yaco na sautaninini ni cicivaki lala, take readings in empty condition. Kevaka sa dau yaco ena gauna ni vakavodoki, take readings when loaded. When it is necessary to measure driveline lengths, measure from joint center to joint center

Me na muria na nona siqeleti itaratara ni caka taumada na angularity raica na. Some manufacturers have found it necessary to vary from the ideal due to geometrical limitations. If vibration persists after adhering to manufacturer’s specifications, contact the manufacturer’s representative.

Na jeke angularity – nodrau Flanges se Yokes

- Sega ni vakawati na Axle lori

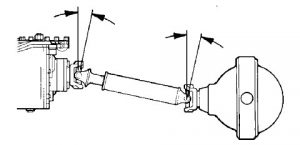

- Biaulivaliva ni o veitosoyaki – Take reading of transmission angle. This angle is the angle to which the rear axle joint angle must match. The transmission angle will have a declination reading of from 0 me 5 ena vuqa na gauna na diqiri.

- Axle kala. Take reading either from machined surface of axle housing or pinion bearing retainer. This angle must be within one degree of the transmission angle.

- Ivakaraitaki: If transmission angle reading is 3 degrees down to the rear, the rear axle angle should be 3 diqiri cake.

- Biaulivaliva ni o veitosoyaki – Take reading of transmission angle. This angle is the angle to which the rear axle joint angle must match. The transmission angle will have a declination reading of from 0 me 5 ena vuqa na gauna na diqiri.

- Axles ni vakamaqosa se lori ena Tabanilotu ni mataisoqosoqo

- Taura na taranisimisani kala wiliwili.

- Take reading from joint of front tandem axle or auxiliary joint. This reading should be within one degree of transmission angle.

- Me kilai: The rear joint of front tandem axle will be the same as the front joint.

- Taura na wiliwili ni cokovata na kala ena axle susugi vakamaqosa, or axle to rear of auxiliary. This angle must be within one degree of transmission angle.

Yava cakacaka na iyalayala ni o veitosoyaki (Erau sa veibasai ga)

Isema ni vuravura raraba sa dua na yalayala e cake kala ni cakacaka, vakatau tiko ki na mataqali kei na manufacture. Sa vakaturi me na kala ni cakacaka cokovata ni vakatauvatataki na soqoni cokovata sega ni sivia na 8 e dua na diqiri me baleta na levu drivelines e sivia ni 40″ balavu. Me baleta na levu drivelines ena ruku ni 40″ e dodonu me kakua ni sivia na yalayala e cake ni kala balavu (L) sa tawasei mai vei 5. (Sega ni vakayagataki na yalani oqo me interaxle na drivelines.)

Ivakaraitaki: Me baleta e dua na 35″ driveline, the maximum joint working angle would be 35 plus 5 se na 7degrees. This working angle must not be exceeded.

Place protractor on driveline to obtain angle of driveline from transmission to axle. The difference between the driveline angle and the joint angle is the joint working angle. For instance, Kevaka e na taranisimisani 3 diqiri sobu, and the driveline angle is down 7 ivakatagedegede, the transmission joint working angle is 7 vakalailaitaka 3 se 4 ivakatagedegede.

Ena vakamaqosa na draiva se na installations ni mataisoqosoqo, take readings in the same manner, comparing the universal joint angles to the driveline angle to which it is attached.

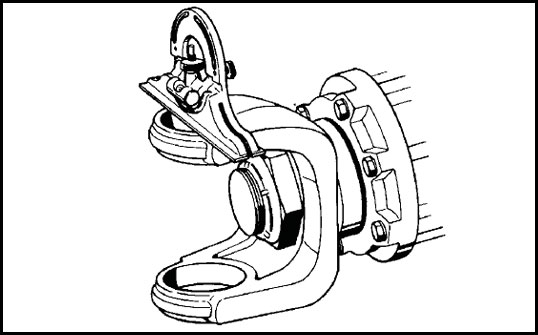

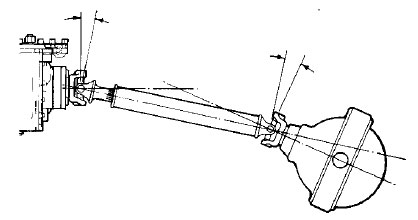

Angularity Checks – Non-Parallel Compensating Angles or Flanges or Yokes

Vata kei na lori ni tawayaga ni lekaleka na yava ni qiqi ka tiko e dua driveline ena kena balavu mai na taranisimisani me axle, na driveline e gadrevi me cicivaki ena bibi sara na musu ni cakacaka ena so installations. Oqo e vakaibalebaletaki talega vei interaxle drivelines. Oqo na na cokovata ni musu cakacaka e vakavuna ki na sautaninini. Me vakalailaitaki kina na kena na idavodavo ni cakacaka, na axle e tilted cake me yacova na laini ni moto ni pinion kei na taranisimisani mainshaft laini intersect veimama kei na cokovata ni valenivolavola.

Ena vakamaqosa na draiva axles, the rearward axle is tilted upward until its pinion shaft centerline and forward axle pinion shaft centerline intersect midway between joint centers.

Ni vaka ni installations cokovata ni sega-erau sa veibasai ga sa rawa, it is necessary to take the driveline angle readings as well as transmission and axle angle readings.

- Sega ni vakawati na Axle lori

- Kauta kala wiliwili ni biaulivaliva

- Kauta kala ni driveline

- Kauta kala wiliwili ni axle cokovata

- Me compute ni musu donu:

- The difference between the driveline angle and the transmission angle will be the transmission joint working angle.

- The difference between the driveline angle and the axle angle will be the axle joint working angle.

- The two working angles of transmission and axle must be equal.

- Ivakaraitaki:

Sa ikoya na taranisimisani 3 diqiri sobu

E na driveline 7.5 diqiri sobu

E dakudra axle 12 diqiri sobu

Sa 7.5 vakalailaitaka 3 tautauvata 4.5 ivakatagedegede

12 vakalailaitaka 7.5 tautauvata 4.5 ivakatagedegede, giving 4.5 equal working angles

- Axles ni vakamaqosa se lori ena Tabanilotu ni mataisoqosoqo – When taking readings on tandem drive axles or between auxiliary and rear axle, the same principles apply as with single axle vehicles. Take readings between transmission and front tandem axle, or auxiliary. Take readings between axles or between auxiliary and axle. Ena dua tale na kena vosa, take angle readings for each set of universal joints

Yava cakacaka na iyalayala ni o veitosoyaki (Sega-erau sa veibasai ga)

Sa vakaturi me na yalayala e cake cokovata cakacaka ni o veitosoyaki me baleta na soqoni cokovata ni sega-erau sa veibasai ga kakua ni sivia na balavu ni driveline levu sa tawasei mai vei 10. Me kena ivakaraitaki, Kevaka sa ikoya na balavu ni levu na driveline 55, sai koya na yalayala e cake na cokovata ni kala cakacaka 55 sa tawasei mai vei 10 se 5.5 ivakatagedegede. (Sega ni vakayagataki na yalani oqo me interaxle na drivelines.)

Veisau ni axle

Axle musu me vakararaba ni moici mai vua e dua vei ira na sala oqo, vakatau tiko ki na mataqali axle.

- Moica na titoko ni torque, Kevaka adjustable na mataqali.

- Add to or reduce length of non-adjustable torque rods.

- Add or reduce the number of shims behind torque rod brackets.

- Use correct amount of wedge shims under spring to axle pad.

Suspensions – kala ni moto ni Pinion

Sa na lailai se sega na veisau ni axle pinion kala vata kei na mataqali suspensions ka e dua na itosotoso ni parallelogram. Oqo sa vakatara na differential na housings me ra veitosoyaki cake ka lako sobu ena na sala vola ena gauna ni veisele.

Ena vakatara na suspensions e sega ni dua na itosotoso ni parallelogram vei ira na axle pinion moto me oscillate ena dua arc, me dau veisau kala ni moto ni pinion ena gauna ni veisele. E dua na duidui levu ni sautaninini e rawa ni yaco vakarota ena musu ni cakacaka ni na isema ni vuravura raraba sa yalolailai kidrowa.

Sa na sega ni vakawati na draiva ni lori ni axle na lailai se sega na veisau ni axle pinion kala ena gauna ni veisele.

E dua tiki ni biaulivaliva o na gadreva e tu vei! Dua ga na siga vakauyaya tu, e vuravura raraba.

GADREVA NA GALALA NA VEITOKONI MAI VUA E DUA NA KENADAU?