Aandrijflijn Hoekigheid Probleme

torsie Vibrasie

Nagaan aandrijflijn U-Gesamentlike Operasie Hoeke

Die aksie van 'n aandrijflijn met 'n kruiskoppeling aan albei kante werk deur 'n hoek resultate in 'n eienaardige beweging. Die aandrijflijn sal bespoedig en vertraag twee keer vir elke revolusie. As die werk hoeke aan albei kante van die skag is ongelyke, torsie trilling resultate. Dit torsie trilling sal neig om homself uit te kanselleer indien beide gesamentlike werk hoeke gelyk is.

Tipes Geraas

Geraas of vibrasie wat kom net by sekere pad spoed en verminder as spoed toeneem is oor die algemeen veroorsaak deur ongelyke werkende hoeke aandryf- gewrigte. Geraas of vibrasie wat aanhoudend dwarsdeur die spoed reeks en wissel in intensiteit met verandering van spoed kan veroorsaak word deur ongebalanseerde drivelines, ongebalanseerde remtrommels of skyfies, of drivelines met kruiskoppelings uit fase.

voorlopige Tjeks

Maak tjeks van die volgende voordat hoek lesings:

- Check companion flange or yoke nut for looseness and torque to proper specification if necessary.

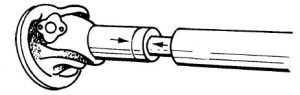

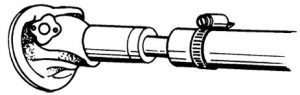

- Driveline slip joints that do not have the arrows or other markings pointing to each other will result in the driveline universal joints being out of phase. Met ander woorde, the transmission universal joint may be turned one spline or more to the right or left of being aligned with the universal joint at the opposite end of the driveline.

- Some computer designed drivelines are purposely built with U-joints out of phase. Check manufacturer’s specifications for proper setting. ook, check closely to make certain no twist has occurred to the tubing, causing these two joints to be out of phase Make sure the slip joint works freely and is not bound or seized. Slip joints must absorb axle housing movements.

- Unbalanced drivelines can cause vibration that occurs throughout the speed range of vehicle and varies in intensity with a change of speed. The driveline may be at fault in respect to balance and concentricity. A quick field check to determine driveline balance can be made by securing a small piece of metal or similar weight with a hose clamp to the front of the tube where the splined shaft is welded. Road test the vehicle and continue to move the weight around the tube until the balance point is found and vibration disappears or is minimized.

Drivelines is dinamies gebalanseer om hul beoogde rotasie snelheid en nie na oneindige spoed. so, vibration can be expected when this rotational velocity is exceeded. Check concentricity of driveline by mounting on lathe centers and dial indicating. Check spesifikasies vervaardiger se vir slijtage toelae. - Enjin ondersteun wat gedra word, gebreekte of los, and mounting pads that are worn or deteriorated must be corrected to restore the engine suspension to its original vibration tolerance.

neem Lesings

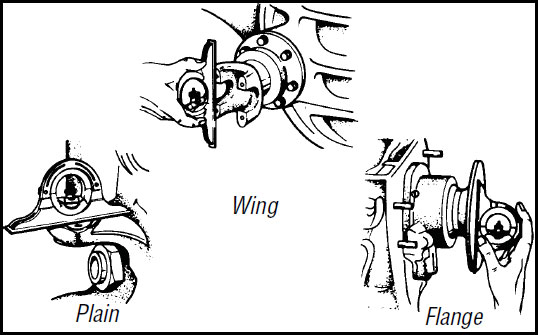

Take readings with protractor from machined surfaces of yokes or companion flanges. Plain, vleuel of tipe flens gewrigte ondervind mag word. Some will require partial disassembly to obtain accurate readings.

Op plain tipe gewrigte, it may be necessary to remove the bearing cap. Wanneer die neem van lesings, make sure the universal joint is in a vertical plane. At the rear axle, take readings from a machined surface differential carrier that is in the same plane as the axle pinion shaft, of vanaf bewerkte oppervlak wat loodreg op kleinrat skag, wat ook al makliker.

As vibrasie ontstaan, terwyl die maatskappy leë, take readings in empty condition. As dit gebeur wanneer gelaai, take readings when loaded. When it is necessary to measure driveline lengths, measure from joint center to joint center

spesifikasies vervaardiger se gevolg moet word wanneer die maak van die aanvanklike hoekigheid tjek. Some manufacturers have found it necessary to vary from the ideal due to geometrical limitations. If vibration persists after adhering to manufacturer’s specifications, contact the manufacturer’s representative.

Hoekigheid Tjeks - Parallelle Flense of Jukke

- Enkele as Voertuie

- transmissie hoek – Take reading of transmission angle. This angle is the angle to which the rear axle joint angle must match. The transmission angle will have a declination reading of from 0 om 5 grade in die meeste gevalle.

- axle hoek. Take reading either from machined surface of axle housing or pinion bearing retainer. This angle must be within one degree of the transmission angle.

- voorbeeld: If transmission angle reading is 3 degrees down to the rear, the rear axle angle should be 3 grade tot.

- transmissie hoek – Take reading of transmission angle. This angle is the angle to which the rear axle joint angle must match. The transmission angle will have a declination reading of from 0 om 5 grade in die meeste gevalle.

- Tandemasse of Voertuie met Hulp Eenhede

- Neem oordrag hoek lees.

- Take reading from joint of front tandem axle or auxiliary joint. This reading should be within one degree of transmission angle.

- nota: The rear joint of front tandem axle will be the same as the front joint.

- Neem lees van gesamentlike hoek by tandem agteras, or axle to rear of auxiliary. This angle must be within one degree of transmission angle.

Gesamentlike Working Angle Limits (parallel)

Kruiskoppelings het 'n maksimum werkende hoek, afhangende van die tipe en vervaardiging. Dit word aanbeveel dat die gesamentlike werk hoek vir parallel gesamentlike vergadering nie oorskry 8 grade vir hoof drivelines meer as 40″ lank. Vir belangrikste drivelines onder 40″ die maksimum hoek moet nie langer as Lengte (L) gedeel deur 5. (Hierdie limiet geld nie vir drivelines interaxle.)

voorbeeld: Vir 'n 35″ aandrijflijn, the maximum joint working angle would be 35 plus 5 of 7degrees. This working angle must not be exceeded.

Place protractor on driveline to obtain angle of driveline from transmission to axle. The difference between the driveline angle and the joint angle is the joint working angle. For instance, indien die oordrag is 3 grade af, and the driveline angle is down 7 grade, the transmission joint working angle is 7 minus 3 of 4 grade.

Op 'n tandem ry of hulp installasies, take readings in the same manner, comparing the universal joint angles to the driveline angle to which it is attached.

Angularity Checks – Non-Parallel Compensating Angles or Flanges or Yokes

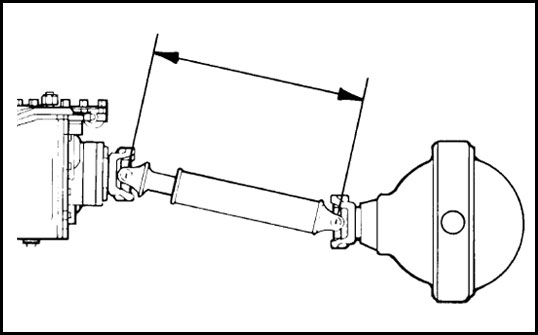

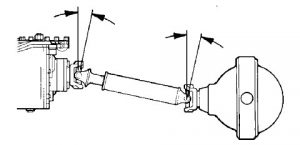

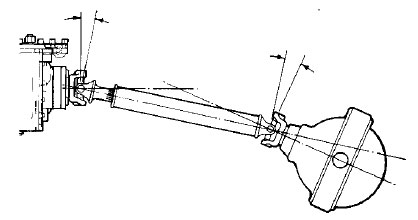

Met 'n kort wielbasis voertuie wat 'n minimum aandrijflijn lengte het van oordrag aan axle, die aandrijflijn is nodig om te werk deur middel van baie ernstige werk hoeke op 'n paar installasies. Dit geld ook vir drivelines interaxle. Hierdie ernstige gesamentlike werk hoeke veroorsaak vibrasie. Om saam te werk hoeke afneem, die as is opwaartse gekantel tot die kleinrat skag middellyn en transmissie mainshaft middellyn sny halfpad tussen die gesamentlike sentrums.

Met tandem ry asse, the rearward axle is tilted upward until its pinion shaft centerline and forward axle pinion shaft centerline intersect midway between joint centers.

Wanneer besyfering nie-parallelle gesamentlike installasies, it is necessary to take the driveline angle readings as well as transmission and axle angle readings.

- Enkele as Voertuie

- Neem hoek lees van oordrag

- Neem hoek aandryf-

- Neem hoek lees van axle gesamentlike

- Om te bereken vir korrekte hoeke:

- The difference between the driveline angle and the transmission angle will be the transmission joint working angle.

- The difference between the driveline angle and the axle angle will be the axle joint working angle.

- The two working angles of transmission and axle must be equal.

- voorbeeld:

oordrag is 3 grade af

aandrijflijn is 7.5 grade af

Agteras is 12 grade af

so 7.5 minus 3 gelyk 4.5 grade

12 minus 7.5 gelyk 4.5 grade, giving 4.5 equal working angles

- Tandemasse of Voertuie met Hulp Eenhede – When taking readings on tandem drive axles or between auxiliary and rear axle, the same principles apply as with single axle vehicles. Take readings between transmission and front tandem axle, or auxiliary. Take readings between axles or between auxiliary and axle. Met ander woorde, take angle readings for each set of universal joints

Gesamentlike Working Angle Limits (Nie Parallel)

Dit word aanbeveel dat die maksimum gesamentlike werk hoek vir nie-parallelle gesamentlike gemeentes die belangrikste aandrijflijn lengte gedeel deur nie meer as 10. Byvoorbeeld, As die hoof aandrijflijn lengte is 55, die maksimum gesamentlike werk hoek 55 gedeel deur 10 of 5.5 grade. (Hierdie limiet geld nie vir drivelines interaxle.)

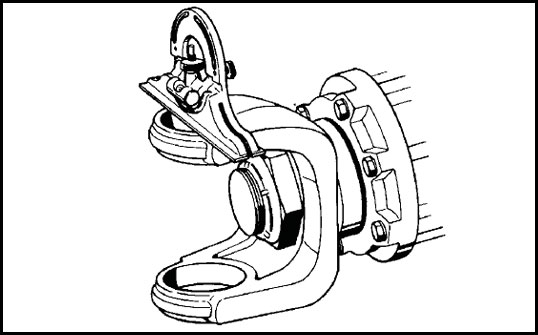

axle Aanpassings

Axle hoeke kan oor die algemeen aangepas deur een van die volgende maniere, afhangende van die tipe van axle.

- Eers wringkrag stange, As verstelbare tipe.

- Add to or reduce length of non-adjustable torque rods.

- Add or reduce the number of shims behind torque rod brackets.

- Use correct amount of wedge shims under spring to axle pad.

Skorsings - Pinion Shaft Hoek

Daar sal min of geen verandering van axle kleinrat hoek met tipes skorsings wat 'n parallelogram beweging het. Dit laat ewenaar omhulsels om op en af te beweeg in 'n reguit vertikale tydens die operasie.

Skorsings nie 'n parallelogram beweging sal toelaat axle kleinrat skag te ossilleer in 'n boog, daardeur voortdurend veranderende kleinrat steel hoek tydens die operasie. A wisselende hoeveelheid vibrasie kan voorkom as gevolg van werk hoeke van die kruiskoppelings om 'n oomblik ongelyke.

Enkele ry axle voertuie het min of geen verandering van axle kleinrat hoek tydens die operasie.

Enige transmissie deel wat jy nodig het ons het dit! Dieselfde dag gestuur beskikbaar, wêreldwyd.

Behoefte om vry ondersteuning van een van ons experts?