Eaton Fuller Transmission Troubleshooting Guide

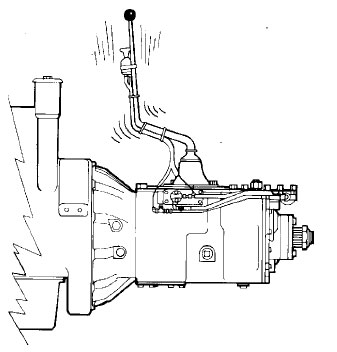

Guide to servicing and repairing Eaton Fuller heavy-duty truck transmission, cuideachadh a 'suidheachadh an cùis sgaoilidh trioblaid, analyze the cause and make necessary repairs for 7, 8, 9, 10, 13, 15 agus 18 cabhag Eaton craoladh. For more in-depth assistance refer to your transmission model service manual or give us a call at 877-776-4600. Tha tar-chur obair gu h-èifeachdach an t-einnsean a ghluasad cumhachd, a thaobh Torc, gus an càr a 'chùlaibh cuibhlichean. Torc 'S e lùbach no cearcallach feachd a lìbhrigeadh le einnsean aig flywheel. Tha tar-chur a 'gear-mheasan àrdachadh no ìsleachadh Torc a rèir na riatanasan a tha a dhìth gus gluasad no tòisich an luchd. Ag ullachadh cuideachd a 'meudachadh no a' lùghdachadh astar. Tha gear-mheasan a tha ceart cho math gun robh an einnsean a bhios ann a 'mhòr-chuid RPM èifeachdach le raon adhartach astar atharrachaidhean. Gus coinneachadh ris an carbad riatanasan, sgaoilidh Feumaidh mheasan Ìosal gu leòr gus tòiseachadh air a 'charbad a' gluasad, a chumail a 'gluasad suas-ìrean, agus a chumail an t-einnsean ag obair ann an àirde èifeachdas raon. Tha tar-chur, cuideachd, Feumaidh a 'toirt dòigh fhurasta airson gear taghadh.

Troubleshooting Guide airson na leanas Eaton Fuller sgaoilidh modailean:

Common Transmission Gearanan

Vibration

Although the effects of vibration will show up in the transmission, vibration usually originates somewhere else in the drive train. Vibration can usually be felt or heard by the driver; ge-tà, ann an cuid de shuidheachaidhean, transmission damage caused by vibration will occur without the driver’s knowledge.

Nithean Transmission Problems Air sgàth Drive Train Vibration:

- Gear Rattle aig leisg

- Gear & shaft splines (fretted)

- Noise

- Fretted Bearings

- Repeated chùlaibh ròn aoidionachd

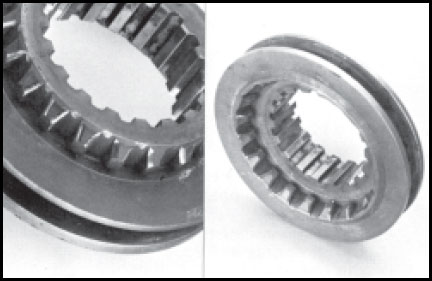

- Broken no sgaoilte synchronizer prìnichean

- Leantainneach loosening de capscrews, eadar camagan agus mountings

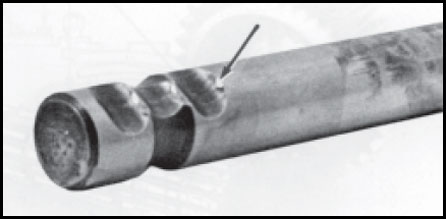

- Cas a bh'air Spine Wear

- Worn universal joints (Neo-craolaidh chomharra, ach thaisbeanair de crathadh.)

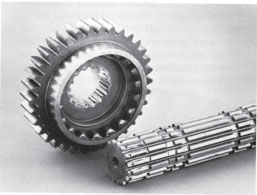

Fretted Splines

Broken Synchronizer Pins

Input Spline Wear

Common causes of vibration include driveline imbalance or misalignment, neo-chothromaichte a cuibhlichean no bhris drumaichean, garbh ruith einnsean, briste no a 'caitheamh einnsean sgeadachadh agus caite crochaidh.

Gear Slipout agus Jumpout

Beulaibh Earrann

Nuair a spèilidh àl a ghluasad a dhol an sàs le mainshaft gear, a 'mairist fiaclan a dh'fheumas a bhith co-shìnte. Chaol no a 'caitheamh a' greimeachadh fiaclan a bhios a 'feuchainn ri "coiseachd" a chèile mar na gèaraichean cuairteachadh. Fo an làimh dheis na h-, slipout Leanaidh. Tha cuid de na tha na h-:

- Transmission muin eccentrically le einnsean flywheel pìleat.

- Cus gear bualadh a 'greimeachadh shortens fiaclan.

- Bidh Clann Ulaidh adjustment iomallach gluasad smachd ceangal thoradh pàirt ann an com-pàirteachas. Cuideachd a 'coimhead airson sgaoilte cheanglaichean agus caite bushings.

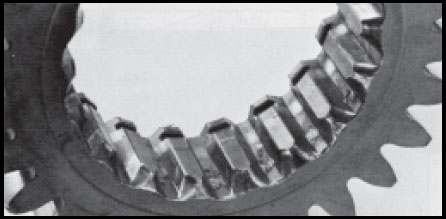

Snubbed greimeachadh Teeth

Gear greimeachadh fiaclan a 'caitheamh gu taper.

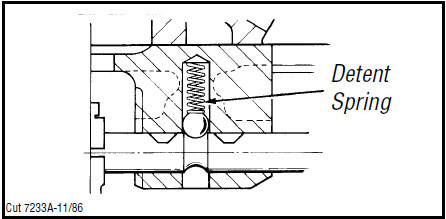

Detent Spring

Brùthadh gu leòr air detent ball bho lag no briste detent as t-earrach.

Bh'air cuing Bar

Cus aodach air detent eag de cuing bar

Cor na h-urrainn a Cause Jumpout

- Extra trom agus fad gluasad stiùirean a dhol, siùdain fasan, bho obair thairis air talamh neo-chòmhnard. Cuipeachadh gnìomha na luamhan overcomes detent aimhreit as t-earrach.

- Mechanical iomallach smachdan leis a 'mhaighstir muin ri frèam a'. Gluasad dàimheach eadar-einnsean-sgaoilidh a 'phasgan agus frèam urrainn toirt air tar-chur a-mach à gèar. Caitheamh no briste einnsean sgeadachadh meudachadh a 'bhuaidh seo staid.

Earrann Auxiliary

Slipout in the auxiliary section may be caused by the clutching teeth being worn, chaol, no nach 'eil gu tur an sàs. These conditions cause the clutch gear to “walk” out of engagement as the gears turn.

Causes of these types of clutching defects are clashing or normal wear after long life. Vibrations set up by an improperly aligned driveline and low air pressure add to the slipout problem.

Jumpout in the auxiliary section usually occurs with the splitter gear set. If torque is not sufficiently broken during splitter shifts, the sliding clutch gear may not have enough time to complete the shift before torque is reapplied to the gears. Mar Torc tha reapplied, the partially engaged clutch gear “jumps” out of the splitter gear. Since the gears have torque applied to them, damage will be done to the clutching teeth of the mating gears.

Hard chaochlaidich

The effort required to move a gear shift lever from one gear position to another varies. If too great an effort is required it will be a constant cause of complaint from the driver.

As gearanan a tha iomallach le seòrsa ceanglaichean a chleachdadh ann an cabover-einnsean carbadan. Before checking the transmission for hard shifting the remote linkage should be inspected. Linkage problems stem from worn connections or bushings, ceangaltach, improper adjustment, lack of lubrication on the joints or an obstruction which restricts free movement. Gus co-dhùnadh ma tha an tar-chur fhèin an adhbhar cruaidh chaochlaidich, gluasad air falbh an luamhan no ceangal bho mhullach na ginealaich. An sin, move the shift blocks into each gear position using a pry bar or screwdriver. If the yoke bars slide easily, 'S e an trioblaid leis a' ceangal a-seanadh. If the trouble is in the transmission, it will generally be caused by one of the following:

- Splines of sliding clutch gear binding on mainshaft as a result of a twisted mainshaft key, bent shift yoke or bowed mainshaft key.

- Cuing bhàraichean ceangaltach anns a 'bhàr taigheadas mar thoradh air taigheadas sgàinte, thar-torqued gluasad bacaidh lockscrew, sprung yoke bar, or swelled areas of the yoke bar.

Ma cruaidh chaochlaidich ann dìreach anns a 'chiad agus an cùl, the shift block detent plunger movement may be restricted. This can result from burrs on the plunger, or from overtightening the plunger spring plug. With the plunger blocked in the depressed position, the plug should be tightened until it bottoms out against the spring, an uair sin taic-mach 1/4 gu 1/2 turn.

Gear bualadh Cha bu chòir iomrall le cruaidh chaochlaidich. Gear clashing occurs when an attempt is made to engage the clutch gear before it has reached synchronization with the mainshaft gear.

Heat

The transmission operating temperature should never exceed 250°F (120° C) airson an ùine-fhada. Ma tha e a ', the oil will breakdown and shorten transmission life.

Leis gu bheil an suathaidh air gluasad pàirtean, transmissions will produce a certain amount of heat. In most cases normal operating temperature is approximately 100°F (40° C) above ambient. Heat is dissipated through the transmission case. When conditions prevent the proper dissipation of heat, then overheating occurs.

Mus coimhead airson ghabhas adhbharan overheating, the oil temperature gauge and sending unit should be inspected to make sure they are giving correct readings.

Causes of Overheating

1. mì-lubrication. Ola ìre ro ìosal no ro àrd, wrong type of oil, or an operating angle of more than 12 ceuman.

2. Ag obair gu cunbhalach fo 20 msu.

3. Àrd-einnsean RPM.

4. Dìomhair adhair sruth timcheall sgaoilidh, due to the transmission being “boxed in” by frame rails, deck lids, tancaichean connaidh agus a 'cur eadar camagan, or by a large bumper assembly.

5. Smùide siostam ro fhaisg air tar-chur.

6. Àrd Ambient Teòthachd.

7. Àrd-each-chumhachd, Overdrive obrachadh.

8. Coasting sìos an cnoc ris an grunn fo mhulad.

Ann an cuid de shuidheachaidhean, an external oil cooler kit can be used to correct overheating problems.

Transmission Ola Coolers tha:

a mholadh

- Le einnseanan de 350 H.P. and above with overdrive transmissions

dhìth

- le einnseanan 399 H.P agus gu h-àrd le Overdrive

craoladh agus GCWs thairis 90,000 puinnd. - le einnseanan 399 H.P. agus os 1400 Lbs.-Ft.

no barrachd Torc - le einnseanan 450 H.P. agus gu h-àrd

Transmission Noise

There will always be a certain level of noise due to the normal transmission operation. Ach, excessive noise or unusual noise such as a whine, growl, or squeal indicates some kind of a problem.

The transmission itself can be the cause of excessive or unusual noise. cuideachd, noise can originate elsewhere in the vehicle, ach a bhith a 'togail agus stèidh nas daingne sgaoilidh.

1. Ghnogadh no Thudding

- gèaraichean - cnapan no swells air gear fiaclan. Such bumps or swells can be removed with a hone or small hand grinder; these areas can be identified as highly polished pots on the face of the gear tooth. San fharsaingeachd, this noise is more prominent when the gear is loaded; mar sin a ', the problem gear can be located as the noise occurs in a specific gear position. Bumps or swells are caused by improper handling of gears before or during assembly.

- Bearings – Noise comes in at low shaft speeds in any position. It is caused by bearings with damaged balls or rollers, or with pitted and spalled raceways.

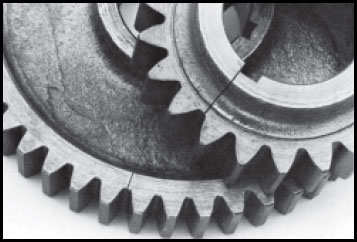

- Cracked Gear – A gear cracked or broken by shock loading or by pressing on shaft during installation will produce this sound at low speeds. Aig àrd-astaran a Howl bhios an làthair.

2. High Pitched Whine or Squeal

- Gear Wear - Toradh àbhaisteach gear aodach, including gear tooth pitting from excessive use. In advanced deterioration, a Howl Leanaidh.

- Mismatched Gear Sets – Such gear sets are identified by an uneven wear pattern on the face of gear teeth.

- Bearings - "ghoid" Bearings, having insufficient axial or radial clearance

3. Growling

- Timing Error – Improper timing of the transmission during reassembly, or improper timing due to gear turning on the countershaft. Both conditions produce an error in tooth spacing.

Causes of Transmission Noise Originating Elsewhere in Vehicle:

- Rough idling einnsean. (fhaicinn gear Rattle)

- Engine obrachaidh fuaim.

- Clutch driven plates in which the dampening action of springs or rubber blocks has been eliminated by wear set or fracture.

- Driveline a-mach à cothromachadh.

- Neo-ionnaine air co-obrachadh ceàrnan.

- Bh'air croisean ann choitcheann altan.

- Loose no caite ionad Bearings.

- Caitheamh no pitted fiaclan air fàinne gear agus pinion de dràibheadh aiseil.

- Cùl aiseil buaidh fàilligeadh.

- Wheels a-mach à cothromachadh.

- A bh'air an t-earrach 'lùbadh air lùdag buaidh.

- Loose "U" Boltaichean.

- Brake drumaichean warped no a-mach à cothromachadh.

Transmission dhuilgheadasan aig Guideline

Following is a basic procedure guideline for troubleshooting transmissions:

- tòiseachaidh Sgrùdadh

- pearsanta Amharc – look for signs of misuse such as broken mounts, uidheam no eadar camagan; check airlines.

- Ceist-sealbhadair no an Operator – gather information on operating conditions and vehicle use, eachdraidh air an duilgheadas, and on shifting characteristics if affected.

- Cruinnich Eachdraidh Aonad – including maintenance and lubrication procedures, seachad air fàilligidhean, agus mìlteachd no hours cleachdaidh.

- Disassemble Transmission

- Keep ola shampall airson truailleadh, dèanamh cinnteach ma bhios feum air.

- Rè disassembly, check for incorrectly installed parts, dhìth pàirtean, and nongenuine parts.

- Glan agus sgrùdadh a dhèanamh air gach pìos gu dlùth.

- Obraich a-mach Seòrsa Mura

- Obraich a-mach agus ceart Adhbhar Mura

The Troubleshooter’s Guideline Chart is used to locate and correct transmission problems. To use the guideline,

1) Locate an tar-chur na thrioblaid anns na bogsaichean gu h-ìosal

2) Hover over the box to see the possible problem and take note of the numbers next to the possible cause

3) Coimheadaibh air an liosta gu h-ìosal agus a 'lorg co-fhreagarrach air àireamh clàraichte ri taobh an duilgheadas. Tha a fhreagras air an àireamh bhon liosta Innsidh an ghabhas correction.

4) Is dòcha gum bi barrachd air aon ghabhas adhbhar agus comasach ceartachadh airson gach trioblaid.

Comasach air a bhith ceartachaidhean:

- Iarraidh air an dràibhear air dràibhidh ceart dòighean.

- Replace pàirtean (after trying other listed possible corrections).

- Sgriubha a 'ghlas-sgriubha mhòr agus retighten gu ceart Torc.

- Coimhead airson a thig milleadh.

- Emery, N. Smooth le pàipear.

- Ath-shuidheachadh gu ceart-chomharrachaidhean.

- Stàlaich dhìth pàirtean.

- Lorg buidhnean-adhair no hoses.

- teannaich phàirt.

- Ceart an cuibhreachadh.

- Recheck àm.

- Clean phàirt.

- Cuir a-steach tana film sileaconach.

- Cuir a-steach sealant.

sam bith sgaoilidh phàirt feumaidh tu feumaidh sinn e! Aon latha luingeis ri fhaotainn, an t-saoghail.

FEUMAIDH taic an-asgaidh bho aon de ar n-eòlaichean?