Eaton Fuller Transmission Fejlfinding

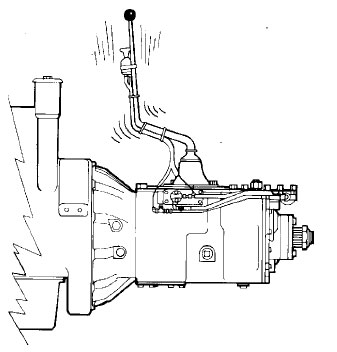

Guide to servicing and repairing Eaton Fuller heavy-duty truck transmission, bistand lokalisere problemet med transmission problemer, analyze the cause and make necessary repairs for 7, 8, 9, 10, 13, 15 og 18 hastighed Eaton transmissioner. For more in-depth assistance refer to your transmission model service manual or give us a call at 877-776-4600. Funktionen transmission er at effektivt at overføre motorens effekt, i form af drejningsmoment, af køretøjets baghjul. Moment er den vridende eller cirkulær kraft leveret af motorens svinghjul. Gearkassens udvekslingsforhold øge eller mindske moment afhængigt af kravene, der er nødvendige for at bevæge sig eller starte lasten. Gearing også øger eller reducerer hastigheden. Gearudvekslingen er korrekt fordelt så at motoren skal drives i den mest effektive RPM området med progressive hastighedsændringer. For at imødekomme bilens krav, transmissionen skal have forhold lav nok til at starte køretøjet bevæger sig, at opretholde bevægelse op-kvaliteter, og at holde motoren opererer i sit højdepunkt effektivitet rækkevidde. transmissionen, også, skal give en nem fremgangsmåde til gearvalg.

Fejlfinding for følgende Eaton Fuller transmission modeller:

Fælles Transmission Klager

Vibration

Although the effects of vibration will show up in the transmission, vibration usually originates somewhere else in the drive train. Vibration can usually be felt or heard by the driver; imidlertid, i nogle tilfælde, transmission damage caused by vibration will occur without the driver’s knowledge.

Nogle Transmission problemer på grund af Drive Train Vibration:

- Gear rangle i tomgang

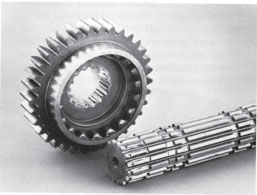

- Gear & shaft splines (fretted)

- Støj

- fretted Lejer

- Gentagen bageste tætning lækage

- Brudte eller løse Synchronizer pins

- Kontinuerlig løsning af maskinskruer, konsoller og monteringer

- Slidt Aksel Spine Wear

- Worn universal joints (Ikke en transmission symptom, men en indikator for vibrationer.)

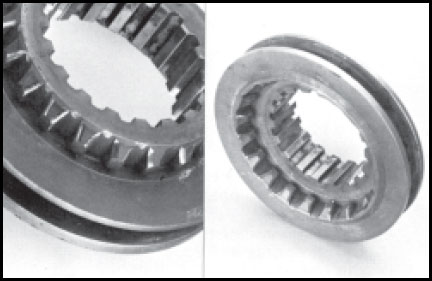

fretted Splines

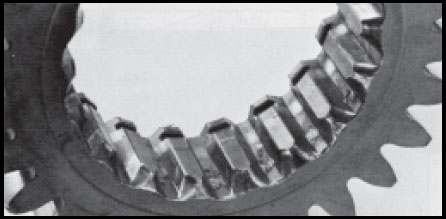

Broken Synchronizer Pins

Input spline Wear

Common causes of vibration include driveline imbalance or misalignment, ubalanceret hjul eller bremsetromler, ru kørende motor, knuste eller slidte motorophæng og nedslidt suspension.

Gear Slipout og Jumpout

Front Sektion

Når en glidende kobling bevæges til indgreb med en mainshaft gear, de samvirkende tænder skal være parallelle. Koniske eller slidte knuget tænder vil forsøge at ”walk” fra hinanden som tandhjulene roterer. Under de rette betingelser, slipout vil resultere. Nogle af disse betingelser er:

- Transmission monteret excentrisk med motorens svinghjul pilot.

- Overdreven gear modstridende hvilket forkorter koblingsmidlerne tænder.

- Forkert indstilling af fjernbetjening skift kontrol binding resulterer i delvis indgreb. Også kontrollere for løse forbindelser og slidte bøsninger.

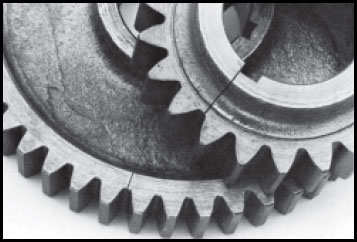

Snubbed krammede Tænder

Gear klamrede tænder iført til en tilspidsning.

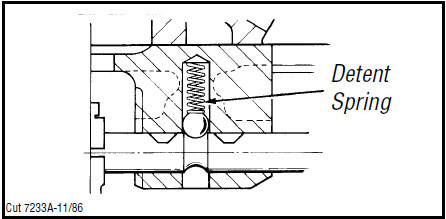

holdefjeder

Utilstrækkeligt tryk på låsekuglen fra svage eller brudt holdefjeder.

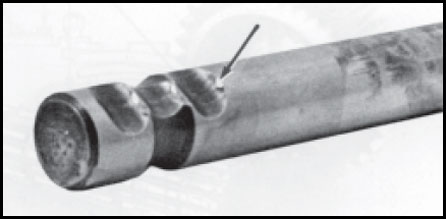

Slidt Yoke Bar

For stort slid på spærreindskæring af åg bar

Forhold, der kan skabe Jumpout

- Ekstra tung og lang skiftehåndtagene der svinger, pendul mode, fra kører over ujævnt terræn. Piskning handling af vægtstangen overvinder palen fjederspændingen.

- Fjernbetjeninger, mekaniske med master monteret på rammen. Relativ bevægelse mellem motor-transmission pakke og rammen kan tvinge transmission i frigear. Slidte eller knækkede motorophæng øge effekten af denne tilstand.

hjælpesektion

Slipout in the auxiliary section may be caused by the clutching teeth being worn, tilspidset, eller fuldt indgreb ikke. These conditions cause the clutch gear to “walk” out of engagement as the gears turn.

Causes of these types of clutching defects are clashing or normal wear after long life. Vibrations set up by an improperly aligned driveline and low air pressure add to the slipout problem.

Jumpout in the auxiliary section usually occurs with the splitter gear set. If torque is not sufficiently broken during splitter shifts, the sliding clutch gear may not have enough time to complete the shift before torque is reapplied to the gears. Som drejningsmoment på igen, the partially engaged clutch gear “jumps” out of the splitter gear. Since the gears have torque applied to them, damage will be done to the clutching teeth of the mating gears.

hårdt Shifting

The effort required to move a gear shift lever from one gear position to another varies. If too great an effort is required it will be a constant cause of complaint from the driver.

De fleste klager er med fjerntliggende koblinger type, der anvendes i Cabover-motor køretøjer. Before checking the transmission for hard shifting the remote linkage should be inspected. Linkage problems stem from worn connections or bushings, binding, improper adjustment, lack of lubrication on the joints or an obstruction which restricts free movement. At afgøre, om transmissionen selv er årsag til hårde gearskift, fjerne gearstangen eller binding fra toppen af transmissionen. Derefter, move the shift blocks into each gear position using a pry bar or screwdriver. If the yoke bars slide easily, problemet er med ledforbindelsessamlingen. If the trouble is in the transmission, it will generally be caused by one of the following:

- Splines of sliding clutch gear binding on mainshaft as a result of a twisted mainshaft key, bent shift yoke or bowed mainshaft key.

- Yoke stænger bindende i bar huset som følge af krakket boliger, over-vrides skift blok lockscrew, sprung yoke bar, or swelled areas of the yoke bar.

Hvis hårde gearskift forekommer kun i første og omvendt, the shift block detent plunger movement may be restricted. This can result from burrs on the plunger, or from overtightening the plunger spring plug. With the plunger blocked in the depressed position, the plug should be tightened until it bottoms out against the spring, derefter bakket ud 1/4 til 1/2 tur.

Gear modstridende bør ikke forveksles med hård gearskift. Gear clashing occurs when an attempt is made to engage the clutch gear before it has reached synchronization with the mainshaft gear.

Varme

The transmission operating temperature should never exceed 250°F (120° C) i en længere periode. Hvis det gør, the oil will breakdown and shorten transmission life.

På grund af friktion af bevægelige dele, transmissions will produce a certain amount of heat. In most cases normal operating temperature is approximately 100°F (40° C) above ambient. Heat is dissipated through the transmission case. When conditions prevent the proper dissipation of heat, then overheating occurs.

Før kontrol for mulige årsager til overophedning, the oil temperature gauge and sending unit should be inspected to make sure they are giving correct readings.

Causes of Overheating

1. Forkert smøring. Oliestanden for lav eller for høj, wrong type of oil, or an operating angle of more than 12 grader.

2. Betjening konsekvent under 20 MPH.

3. Høj motorens omdrejningstal.

4. Begrænset luftstrømning omkring transmission, due to the transmission being “boxed in” by frame rails, deck lids, brændstoftanke og monteringsbeslag, or by a large bumper assembly.

5. Udstødningssystem for tæt på transmission.

6. Høj omgivelsestemperatur.

7. høj hestekræfter, overdrive drift.

8. Friløb ned ad bakke med koblingen deprimeret.

I nogle tilfælde, an external oil cooler kit can be used to correct overheating problems.

Transmission oliekølere er:

Anbefales

- Med motorer af 350 H.P. and above with overdrive transmissions

Nødvendig

- med motorer 399 H.P og ovenfor med overdrive

transmissioner og GCWs end 90,000 lbs. - med motorer 399 H.P. og ovenfor og 1400 Lbs.-Ft.

eller større moment - med motorer 450 H.P. og over

Transmission Støj

There will always be a certain level of noise due to the normal transmission operation. Imidlertid, excessive noise or unusual noise such as a whine, knurre, or squeal indicates some kind of a problem.

The transmission itself can be the cause of excessive or unusual noise. Også, noise can originate elsewhere in the vehicle, men blive afhentet og amplificeret ved transmissionen.

1. Slag eller dunkende

- Gears - bump eller dønninger på gear tænder. Such bumps or swells can be removed with a hone or small hand grinder; these areas can be identified as highly polished pots on the face of the gear tooth. Generelt, this noise is more prominent when the gear is loaded; dermed, the problem gear can be located as the noise occurs in a specific gear position. Bumps or swells are caused by improper handling of gears before or during assembly.

- Lejer – Noise comes in at low shaft speeds in any position. It is caused by bearings with damaged balls or rollers, or with pitted and spalled raceways.

- Cracked Gear – A gear cracked or broken by shock loading or by pressing on shaft during installation will produce this sound at low speeds. Ved høje hastigheder en hyl vil være til stede.

2. High Pitched Whine or Squeal

- Gear Wear - Resultat af normale gear slid, including gear tooth pitting from excessive use. In advanced deterioration, et hyl vil resultere.

- Mismatched Gear Sets – Such gear sets are identified by an uneven wear pattern on the face of gear teeth.

- Lejer - ”sammenklemte” lejer, having insufficient axial or radial clearance

3. knurren

- Timing Error – Improper timing of the transmission during reassembly, or improper timing due to gear turning on the countershaft. Both conditions produce an error in tooth spacing.

Causes of Transmission Noise Originating Elsewhere in Vehicle:

- Groft tomgang motor. (se gear rangle)

- Motor drift støj.

- Clutch driven plates in which the dampening action of springs or rubber blocks has been eliminated by wear set or fracture.

- Drivlinie ude af balance.

- Ulige fælles arbejdsmetoder vinkler.

- Slidte krydser i kardanled.

- Løse eller slidte lejer center.

- Slidte eller udstenede tænder på tandkransen og pinion af drivaksel.

- Bagaksel lejesvigt.

- Hjul ude af balance.

- Slidte fjeder svingleje.

- Løse ”U” bolte.

- Bremsetromler skævt eller ude af balance.

Transmission fejlfinding s retningslinje

Following is a basic procedure guideline for troubleshooting transmissions:

- Indledende inspektion

- Personlig Observation – look for signs of misuse such as broken mounts, beslag eller konsoller; check airlines.

- Spørgsmål ejeren eller operatøren – gather information on operating conditions and vehicle use, på historien om problemet, and on shifting characteristics if affected.

- Saml History of Unit – including maintenance and lubrication procedures, tidligere fiaskoer, og kørte kilometer eller driftstimer.

- Adskil Transmission

- Holde olieprøve for urenheder, kontrollere, hvis nødvendigt.

- Under demontering, check for incorrectly installed parts, manglende dele, and nongenuine parts.

- Rens og inspicere hvert stykke nøje.

- Bestem type fejl

- Bestem og korrekt årsag til svigt

The Troubleshooter’s Guideline Chart is used to locate and correct transmission problems. To use the guideline,

1) Find transmissionen problemet i felterne nedenfor

2) Hover over the box to see the possible problem and take note of the numbers next to the possible cause

3) Der henvises til nedenstående liste og finde det tilsvarende tal er angivet ved siden af problemet. Den matchende nummer fra listen vil fortælle dig den mulige korrektion.

4) Der kan være mere end én mulig årsag og mulig korrektion for hvert problem.

Mulige Korrektioner:

- Instruer driver på ordentlig køreteknik.

- Udskift dele (after trying other listed possible corrections).

- Løsn lock-skruen og spænd til korrekt moment.

- Kig efter resulterende skade.

- Glat med slibepapir.

- Nulstil til ordentlige specifikationer.

- Installer manglende dele.

- Check luftfartsselskaber eller slanger.

- Spænd del.

- Korrigere begrænsningen.

- Kontrollér igen timing.

- ren del.

- Påfør tyndfilm silicone.

- Påfør fugemasse.

Nogen transmissionsdelen du har brug for vi har det! Samme dag shipping til rådighed, i hele verden.

BRUG gratis support fra en af vores EKSPERTER?