Preventative Transmission Maintenance

A good Preventive Maintenance (PM) program for your Eeaton Fuller transmission can avoid breakdowns, or reduce the cost or repairs. Often, transmission problems can be traced directly to poor maintenance. Following is an inspection schedule that may be helpful in setting up a preventive maintenance program. This schedule is not all-inclusive as inspection intervals will vary depending upon operating conditions.

Daily Maintenance

Air Tanks

Bleed air tanks to remove water or oil.

Oil Leaks

Check around bearing covers, PTO covers and other machined surfaces. Also check for oil leakage on the ground before starting truck in the morning.

Every 10,000 Miles Maintenance

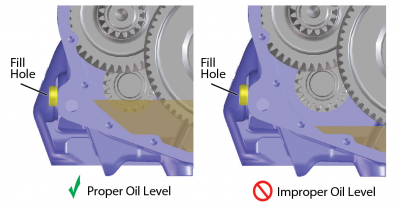

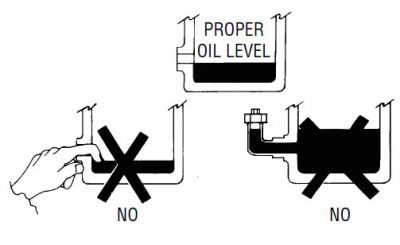

Check Oil Level

Note: Before checking the oil level, engine must be idling & transmission in neutral for at least 2 minutes. Lubricant temperature must be between 60 °F & 120 °F (15.5 °C and 48.8 °C).

Every 20,000 Miles Maintenance

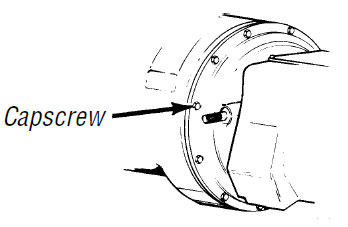

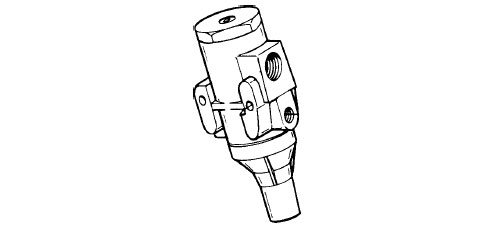

Air System and Connections

Check for leaks, worn hoses and airlines, loose connections and loose capscrews. Check all capscrews in bolt circle of clutch housing for

looseness.

Clutch Housing Mounting

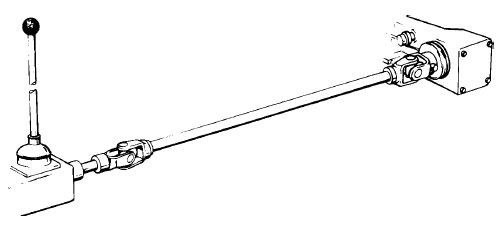

Check Remote Control Linkage

- Check linkage U-joints for wear.

- Check for binding.

- Lubricate U-joints.

- Check for bushing wear.

- Check connections for tightness.

- Check and clean or replace air filter element.

Universal Joint Companion Flange

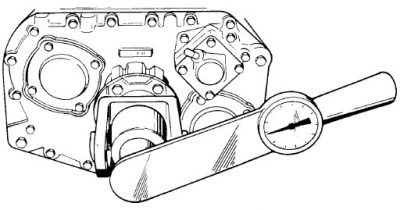

Output Shaft

Pry upward against output shaft to check radial clearance in

mainshaft rear bearing.

Check splines for wear from movement and chucking action

of the universal joint companion flange.

Check for proper torque, 450 to 500 lbs. ft. on twin countershaft models.

Every 40,000 Miles Maintenance

Inspect Clutch

Note: Inspection should be made according to the manufacturer’s specifications.

Check clutch disc faces for wear.

Check dampening action of clutch driven plate.

Release Bearing

Remove hand hole cover and check axial and radial clearance in release bearing.

Check relative position of thrust surface of release bearing with thrust sleeve on push type clutches.

Every *50,000 Miles Maintenance

Change Transmission Lubricant

*Initial fill on new units should be changed at 5,000 miles

Fuller Preventive Maintenance Recommendations

| Preventative Maintenance Operation | Daily | 5,000 | 10,000 | 20,000 | 30,000 | 40,000 | 50,000 | 60,000 | 70,000 | 80,000 | 90,000 | 100,000 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bleed Air Tanks & Listen for Leaks | X | |||||||||||

| Inspect for Oil Leaks | X | |||||||||||

| Check Oil Level | X | X | X | X | X | X | X | X | X | X | ||

| Inspect Air System Connections | X | X | X | X | X | |||||||

| Check Clutch Housing Capscrews for Looseness | X | X | X | X | X | |||||||

| Lube Clutch Pedal Shafts | X | X | X | X | X | |||||||

| Check Remote Control Linkage | X | X | X | X | X | |||||||

| Check & Clean or Replace Air Filter Element | X | X | X | X | X | |||||||

| Check Output Shaft for Looseness | X | X | X | X | X | |||||||

| Check Clutch Operation & Adjustment | X | X | ||||||||||

| Change Transmission Oil | *X | X | X |

*Initial fill on new units. See transmission lubrication page.

REPEAT SCHEDULE AFTER 100,000 MILES

Any transmission part you need we have it! Same day shipping available, worldwide.

NEED FREE SUPPORT FROM ONE OF OUR EXPERTS?