Eaton Fuller Transmission Troubleshooting Guide

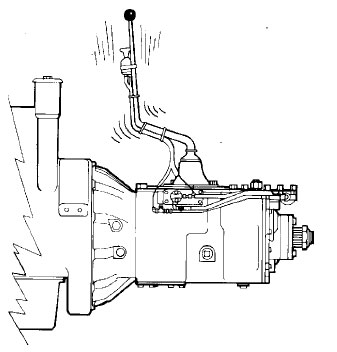

Guide to servicing and repairing Eaton Fuller heavy-duty truck transmission, assistance locating the issue of transmission trouble, analyze the cause and make necessary repairs for 7, 8, 9, 10, 13, 15 and 18 speed Eaton transmissions. For more in-depth assistance refer to your transmission model service manual or give us a call at 877-776-4600. The transmission function is to efficiently transfer the engine’s power, in terms of torque, to the vehicle’s rear wheels. Torque is the twisting or circular force delivered by the engine’s flywheel. The transmission’s gear ratios increase or decrease torque depending on the requirements needed to move or start the load. Gearing also increases or decreases speed. The gear ratios are correctly spaced so that the engine will operate in its most efficient RPM range with progressive speed changes. To meet the vehicle’s requirements, the transmission must have ratios low enough to start the vehicle moving, to maintain movement up-grades, and to keep the engine operating in its peak efficiency range. The transmission, too, must provide an easy method for gear selection.

Troubleshooting Guide for the following Eaton Fuller transmission models:

Common Transmission Complaints

Vibration

Although the effects of vibration will show up in the transmission, vibration usually originates somewhere else in the drive train. Vibration can usually be felt or heard by the driver; however, in some cases, transmission damage caused by vibration will occur without the driver’s knowledge.

Some Transmission Problems Due to Drive Train Vibration:

- Gear rattle at idle

- Gear & shaft splines (fretted)

- Noise

- Fretted Bearings

- Repeated rear seal leakage

- Broken or loose synchronizer pins

- Continuous loosening of capscrews, brackets and mountings

- Worn Shaft Spine Wear

- Worn universal joints (Not a transmission symptom, but an indicator of vibration.)

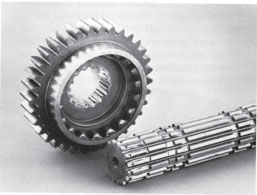

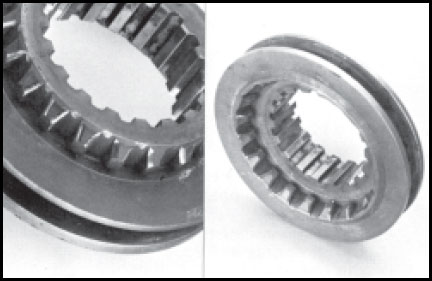

Fretted Splines

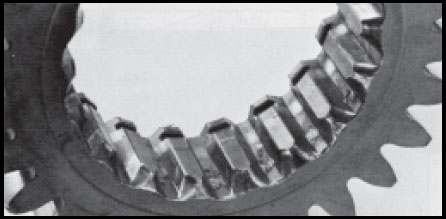

Broken Synchronizer Pins

Input Spline Wear

Common causes of vibration include driveline imbalance or misalignment, unbalanced wheels or brake drums, rough running engine, broken or worn engine mounts and worn suspension.

Gear Slipout and Jumpout

Front Section

When a sliding clutch is moved to engage with a mainshaft gear, the mating teeth must be parallel. Tapered or worn clutching teeth will try to “walk” apart as the gears rotate. Under the right conditions, slipout will result. Some of these conditions are:

- Transmission mounted eccentrically with engine flywheel pilot.

- Excessive gear clashing which shortens clutching teeth.

- Incorrect adjustment of remote shift control linkage resulting in partial engagement. Also check for loose connections and worn bushings.

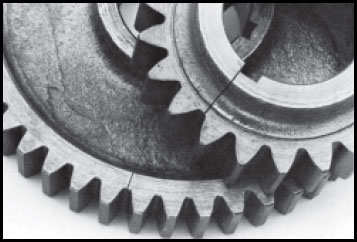

Snubbed Clutching Teeth

Gear clutching teeth wearing to a taper.

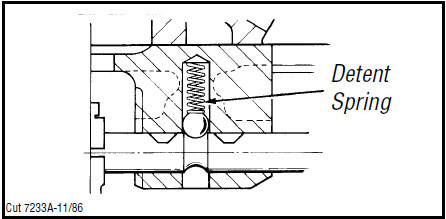

Detent Spring

Insufficient pressure on detent ball from weak or broken detent spring.

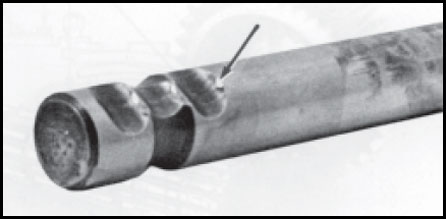

Worn Yoke Bar

Excessive wear on detent notch of yoke bar

Conditions That Can Cause Jumpout

- Extra heavy and long shift levers which swing, pendulum fashion, from operating over uneven terrain. Whipping action of the lever overcomes detent spring tension.

- Mechanical remote controls with the master mounted to the frame. Relative movement between engine-transmission package and frame can force transmission out of gear. Worn or broken engine mounts increase the effects of this condition.

Auxiliary Section

Slipout in the auxiliary section may be caused by the clutching teeth being worn, tapered, or not fully engaged. These conditions cause the clutch gear to “walk” out of engagement as the gears turn.

Causes of these types of clutching defects are clashing or normal wear after long life. Vibrations set up by an improperly aligned driveline and low air pressure add to the slipout problem.

Jumpout in the auxiliary section usually occurs with the splitter gear set. If torque is not sufficiently broken during splitter shifts, the sliding clutch gear may not have enough time to complete the shift before torque is reapplied to the gears. As torque is reapplied, the partially engaged clutch gear “jumps” out of the splitter gear. Since the gears have torque applied to them, damage will be done to the clutching teeth of the mating gears.

Hard Shifting

The effort required to move a gear shift lever from one gear position to another varies. If too great an effort is required it will be a constant cause of complaint from the driver.

Most complaints are with remote type linkages used in cabover-engine vehicles. Before checking the transmission for hard shifting the remote linkage should be inspected. Linkage problems stem from worn connections or bushings, binding, improper adjustment, lack of lubrication on the joints or an obstruction which restricts free movement. To determine if the transmission itself is the cause of hard shifting, remove the shift lever or linkage from the top of the transmission. Then, move the shift blocks into each gear position using a pry bar or screwdriver. If the yoke bars slide easily, the trouble is with the linkage assembly. If the trouble is in the transmission, it will generally be caused by one of the following:

- Splines of sliding clutch gear binding on mainshaft as a result of a twisted mainshaft key, bent shift yoke or bowed mainshaft key.

- Yoke bars binding in the bar housing as a result of cracked housing, over-torqued shift block lockscrew, sprung yoke bar, or swelled areas of the yoke bar.

If hard shifting occurs only in first and reverse, the shift block detent plunger movement may be restricted. This can result from burrs on the plunger, or from overtightening the plunger spring plug. With the plunger blocked in the depressed position, the plug should be tightened until it bottoms out against the spring, then backed out 1/4 to 1/2 turn.

Gear clashing should not be confused with hard shifting. Gear clashing occurs when an attempt is made to engage the clutch gear before it has reached synchronization with the mainshaft gear.

Heat

The transmission operating temperature should never exceed 250°F (120°C) for an extended period of time. If it does, the oil will breakdown and shorten transmission life.

Because of the friction of moving parts, transmissions will produce a certain amount of heat. In most cases normal operating temperature is approximately 100°F (40°C) above ambient. Heat is dissipated through the transmission case. When conditions prevent the proper dissipation of heat, then overheating occurs.

Before checking for possible causes of overheating, the oil temperature gauge and sending unit should be inspected to make sure they are giving correct readings.

Causes of Overheating

1. Improper lubrication. Oil level too low or too high, wrong type of oil, or an operating angle of more than 12 degrees.

2. Operating consistently under 20 MPH.

3. High engine RPM.

4. Restricted air flow around transmission, due to the transmission being “boxed in” by frame rails, deck lids, fuel tanks and mounting brackets, or by a large bumper assembly.

5. Exhaust system too close to transmission.

6. High ambient temperature.

7. High horsepower, overdrive operation.

8. Coasting downhill with the clutch depressed.

In some cases, an external oil cooler kit can be used to correct overheating problems.

Transmission Oil Coolers are:

Recommended

- With engines of 350 H.P. and above with overdrive transmissions

Required

- With engines 399 H.P and above with overdrive

transmissions and GCWs over 90,000 lbs. - With engines 399 H.P. and above and 1400 Lbs.-Ft.

or greater torque - With engines 450 H.P. and above

Transmission Noise

There will always be a certain level of noise due to the normal transmission operation. However, excessive noise or unusual noise such as a whine, growl, or squeal indicates some kind of a problem.

The transmission itself can be the cause of excessive or unusual noise. Also, noise can originate elsewhere in the vehicle, but be picked up and amplified by the transmission.

1. Knocking or Thudding

- Gears – Bumps or swells on gear teeth. Such bumps or swells can be removed with a hone or small hand grinder; these areas can be identified as highly polished pots on the face of the gear tooth. Generally, this noise is more prominent when the gear is loaded; thus, the problem gear can be located as the noise occurs in a specific gear position. Bumps or swells are caused by improper handling of gears before or during assembly.

- Bearings – Noise comes in at low shaft speeds in any position. It is caused by bearings with damaged balls or rollers, or with pitted and spalled raceways.

- Cracked Gear – A gear cracked or broken by shock loading or by pressing on shaft during installation will produce this sound at low speeds. At high speeds a howl will be present.

2. High Pitched Whine or Squeal

- Gear Wear – Result of normal gear wear, including gear tooth pitting from excessive use. In advanced deterioration, a howl will result.

- Mismatched Gear Sets – Such gear sets are identified by an uneven wear pattern on the face of gear teeth.

- Bearings –“Pinched” bearings, having insufficient axial or radial clearance

3. Growling

- Timing Error – Improper timing of the transmission during reassembly, or improper timing due to gear turning on the countershaft. Both conditions produce an error in tooth spacing.

Causes of Transmission Noise Originating Elsewhere in Vehicle:

- Rough idling engine. (see gear rattle)

- Engine operating noise.

- Clutch driven plates in which the dampening action of springs or rubber blocks has been eliminated by wear set or fracture.

- Driveline out of balance.

- Unequal joint working angles.

- Worn crosses in universal joints.

- Loose or worn center bearings.

- Worn or pitted teeth on ring gear and pinion of driving axle.

- Rear axle bearing failure.

- Wheels out of balance.

- Worn spring pivot bearing.

- Loose “U” bolts.

- Brake drums warped or out of balance.

Transmission Troubleshooter’s Guideline

Following is a basic procedure guideline for troubleshooting transmissions:

- Preliminary Inspection

- Personal Observation – look for signs of misuse such as broken mounts, fittings or brackets; check airlines.

- Question the Owner or Operator – gather information on operating conditions and vehicle use, on the history of the problem, and on shifting characteristics if affected.

- Gather History of Unit – including maintenance and lubrication procedures, past failures, and mileage or hours of use.

- Disassemble Transmission

- Keep oil sample for impurities, check if needed.

- During disassembly, check for incorrectly installed parts, missing parts, and nongenuine parts.

- Clean and inspect each piece closely.

- Determine Type of Failure

- Determine and correct Cause of Failure

The Troubleshooter’s Guideline Chart is used to locate and correct transmission problems. To use the guideline,

1) Locate the transmission problem in the boxes below

2) Hover over the box to see the possible problem and take note of the numbers next to the possible cause

3) Refer to the list below and locate the corresponding number listed next to the problem. The matching number from the list will tell you the possible correction.

4) There may be more than one possible cause and possible correction for each problem.

Possible Corrections:

- Instruct driver on proper driving techniques.

- Replace parts (after trying other listed possible corrections).

- Loosen lock-screw and retighten to proper torque.

- Look for resultant damage.

- Smooth with emery paper.

- Reset to proper specifications.

- Install missing parts.

- Check airlines or hoses.

- Tighten part.

- Correct the restriction.

- Recheck timing.

- Clean part.

- Apply thin film silicone.

- Apply sealant.

Any transmission part you need we have it! Same day shipping available, worldwide.

NEED FREE SUPPORT FROM ONE OF OUR EXPERTS?