Eaton Fuller Hybrid Transmission Fault Code 107 – High Voltage Battery Leak Detection Fault

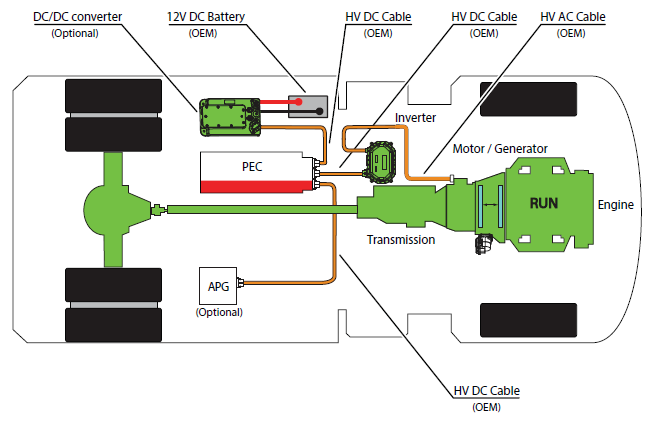

Fault code for Eaton Hybrid Drive Systems models (MY09) EH-8E406A-U/P, EH-8E406A-UP, EH-8E406A-UPG, EH-8E406A-CD, EH-8E406A-CDG, EH-8E406A-CDR, EH-8E406A-T, EH-6E706B-CD, EH-6E706B-P and EH-6E706B-UPG. Read below to learn how to test, clear and fix fault code errors for your Freightliner, Mack, Peterbilt, Kenworth, Volvo, International, and heavy-duty truck and equipment. The Battery Control Unit (BCU) within the Power Electronics Carrier (PEC) continuously monitors Hybrid high-voltage leakage being reported to the DC circuit of the PEC.

Fault Code 107 – High Voltage Battery Leak Detection Fault Detection

The following preconditions must be met before the system detects the fault:

- Inverter ignition voltage is greater than 7 volts and less than 16 volts.

- PEC ignition voltage is greater than 7 volts and less than 16 volts.

Note: When troubleshooting an Inactive code refer to the Product Diagnostic Mode (PDM)

Conditions to Set Fault Code Active

- FMI 1 is set when resistance between High Voltage cables and shielding is less than 220K Ohms for 5 seconds.

- FMI 11, 30 is set when there is an invalid leak detection signal for 2 minutes.

Fallback When Fault Code 107 is set the following conditions occur:

- Amber “Check Hybrid” light illuminates.

- Fault is stored in Hybrid Control Module (HCM) memory.

- Inverter shuts off high-voltage system.

- HCM continues to control the hybrid vehicle in a diesel-only mode.

- Transmission defaults start gear to 1st.

Conditions to Set Fault Code Inactive

Only Inactive faults can be cleared from the Transmission Electronic Control Unit (TECU) or HCM history using ServiceRanger. The TECU automatically clears the faults from history after 200 hours and the HCM automatically clears the faults from history after the fault has been Inactive for 200 hours.

This fault code can be caused by any of the following:

- FMI 1, 11, 30

- High-voltage cable insulation damage

- High-voltage component leaking

- Water or moisture in a high-voltage connector or component.

Fault Code 107 – High Voltage Battery Leak Detection Fault Test

Component Identification:

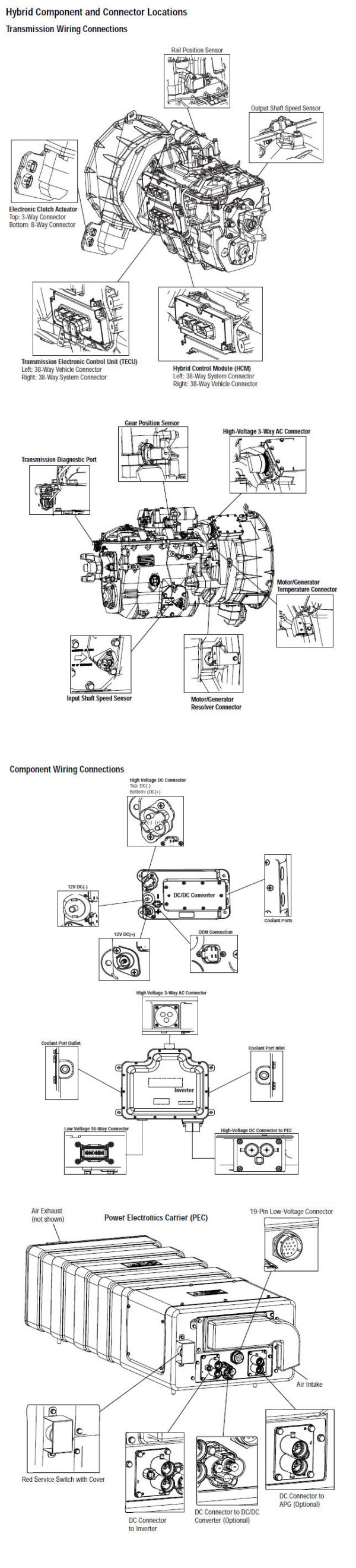

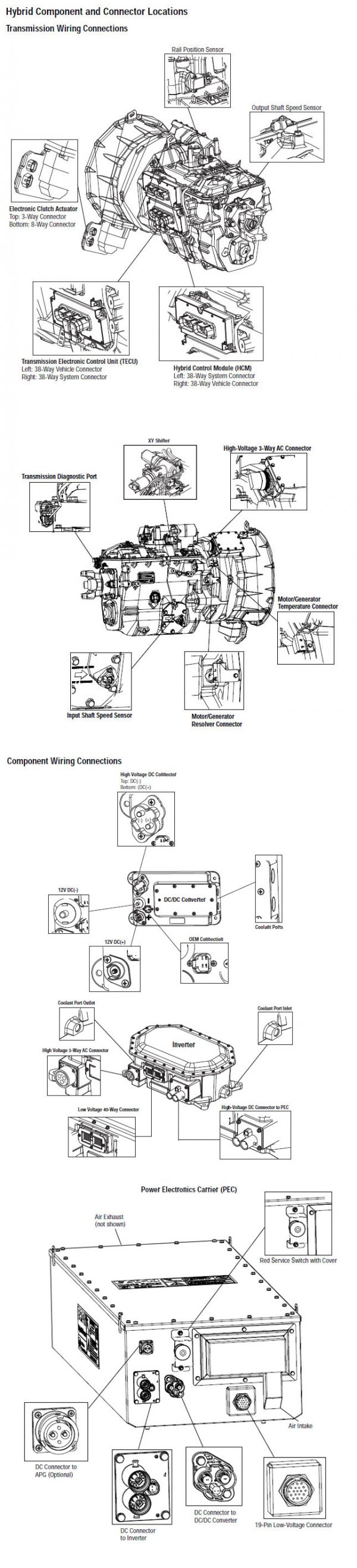

NOTE: Refer to the Eaton Hybrid Component and Connector Location for Connector Locations in MY09 Systems.

Warnings & Cautions

Warning: Warning indicates an immediate hazard, which could result in severe personal injury if you do not follow the indicated procedure.

Caution: Caution indicates vehicle or property damage could occur if you do not follow the indicated procedure.

Note: Note indicates additional detail that will aid in the diagnosis or repair of a component/system.

Follow the specified procedures in the indicated order to avoid personal injury:

1. If the high-voltage cones are around the vehicle and the lockout is installed on the PEC, the only person that should be allowed to start the vehicle is the person who signed the lockout tag.

2. Before working on a vehicle or leaving the cab while the engine is running, you should place the shift lever in “N” set the parking brake, and block the wheels.

3. For safety reasons, always engage the service brakes prior to selecting gear positions from “N.”

4. Before starting a vehicle always be seated in the driver’s seat, select “N” on the shift control, and set the parking brakes.

5. In vehicles with ePTO, the engine and/or

Motor/Generator can start in ePTO mode. Never perform any maintenance or work on vehicle, while in this mode.

6. 12-Volt Battery positive (+) and negative (-) must be disconnected prior to any welding on any Hybrid equipped vehicle.

Caution: Follow the specified procedures in the indicated order to avoid equipment malfunction or damage.

Caution: Do not release the parking brake or attempt to select a gear until the air pressure is at the correct level.

Caution: To avoid damage to the transmission during towing place the shift lever in “N” and lift the drive wheels off the ground or disconnect the driveline.

High-Voltage Warnings & Cautions

- Use CO2 or Dry Chemical Fire Extinguishers.

- The high-voltage wiring is covered in orange insulation or convoluted tubing and marked with warning labels at the connectors.

- All Eaton® Hybrid Diesel/Electric vehicles will be marked ‘Hybrid’ on the outside of the vehicle, along with the shift label on the dash.

- Refer to OEM for specific location of chassis mounted hybrid components.

- Do NOT cut into the orange high-voltage cables.

- Do NOT cut into or open the PEC.

- Do NOT cut into or open the DC/DC Converter.

- Do NOT cut into or open the Inverter.

A buffer zone must be set up and high-voltage insulated rubber gloves (class 0 with leather protectors) are required prior to working on high-voltage. Failure to follow these instructions may result in severe personal injury or death.

The rubber-insulated gloves that must be worn while working on the high-voltage system are class 0 with leather protectors. The rubber gloves should be tested before EVERY use following the rubber insulation gloves testing procedure found in “Diagnostic Tools/Service Publications” on page 6. Failure to follow these instructions may result in severe personal injury or death.

Before inspecting or working on any high-voltage cables or components the “High-Voltage Service Shutdown and Power-Up Procedure” on page 4 should be followed. Failure to follow these instructions may result in severe personal injury or death.

The Lockout and Tagout devices should only be removed by the technician that placed the Lockout and Tagout devices on the vehicle. Failure to follow these instructions may result in severe personal injury or death.

High-voltage rubber insulated gloves (class 0 with leather protectors) must be worn when working on any

high-voltage cables. The “High-Voltage Service Shutdown and Power-Up Procedure” on page 4 must be followed prior to removing any high-voltage cables. Failure to follow these instructions may result in severe personal injury or death.

High-voltage cables and wiring are orange and contain a warning label at the connectors. High-voltage components are marked with a label. High-voltage rubber insulated gloves (class 0 with leather protectors) must be used when working on any of these components. Failure to follow these instructions may result in severe personal injury or death.

High-Voltage Service Shutdown Procedures

1. Follow “High-Voltage Work Area” procedure.

1. Follow “High-Voltage Work Area” procedure.

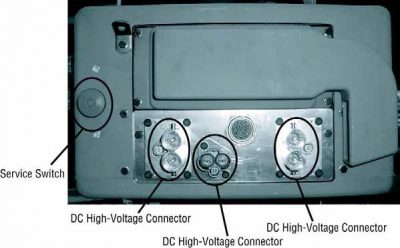

2. Locate the red PEC Service Switch on the front of the PEC and push switch off.

3. Remove the Service Switch Cover and install the Lockout Bracket (J48506).

4. Fasten tag to the Lockout Bracket.

5. Ensure the PEC Service Switch can not move from the off position.

6. Allow the system to set for a minimum of 5 minutes to discharge high voltage.

7. Connect ServiceRanger and view the Data Monitor PID 116 called “High-Voltage Battery Potential.” Use SPN 520323 for J1939 connection “Battery Voltage RB” (Relay Box).

8. The voltage should be 30 volts or less. If the voltage is above 30 volts, do not work on the vehicle and contact Eaton® at 1-800-826-HELP (4357).

9. Turn ignition key off and proceed to repair or troubleshooting step.

Note: The voltage drops to zero when the key is off.

High-Voltage Service Power-Up Procedure

1. Install all high-voltage connectors into their locked positions.

2. If you are the person working on the vehicle, remove the Lockout Bracket and tag.

3. Reinstall the Lockout Bracket over the Service Switch.

4. Pull the Service Switch out and let vehicle set for 2 minutes.

5. Start vehicle when appropriate.

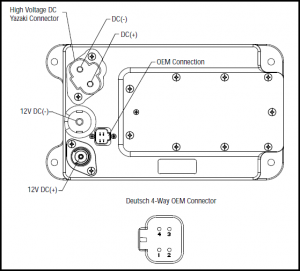

Eaton Hybrid Component and Connector Location

Eaton Hybrid Component and Connector Location MY09 Systems

STEP 1. Check for Active or Inactive fault code status.

- Review and follow the Warnings & Cautions.

- Key on.

- Retrieve Active fault codes and FMIs with ServiceRanger using the 9-Way Diagnostic Connector or manually.

- If Fault Code 107 is Active, go to Step 2.

- If Fault Code 107 is Inactive, test is complete, go to Step 11.

STEP 2. Measure the resistance of the AC cable disconnected at the inverter to the motor / generator.

- Is the vehicle equipped with an Auxiliary Power Generator (APG)? Is the fault code set while driving or when the APG is in being used? If Yes call

(800) 826-4357 and follow the Hybrid Prompts for assistance.

Danger: See High-Voltage Service Shutdown and Power-Up Procedures. Follow the procedures to avoid shock, burn or death from improperly handled high-voltage. - Key off.

- Disconnect the inverter AC connector at the inverter. The AC cable should not be disconcerted from the Motor/ Generator. Inspect AC cable connector and inverter AC connection for moisture or contamination.

- Measure the resistance of the AC 3-phase pins: Note: The AC cable should still be connected to the Motor/Generator.

- Pin A to Cable Shield

- Pin B to Cable Shield

- Pin C to Cable Shield

- If moisture or contamination is found, this is a non-Eaton failure. See OEM for repair direction.

- If resistance is OL or outside range, go to Step 5.

- If resistance is between 0–220K ohms, go to Step 3.

STEP 3. Measure the resistance of the AC cable that is disconnected from the Inverter and the motor / generator.

- If you are coming here from Step 2 a high voltage shutdown should have already been performed and the key should be in the “off” position. If this has been completed continue to # 2.

Note: If the high voltage shutdown procedure has not performed return to the beginning of this procedure.

Danger: See High-Voltage Service Shutdown and Power-Up Procedures. Follow the procedures to avoid shock, burn or death from improperly handled high-voltage. - Disconnect the AC connector at the Motor/ Generator. The AC cable should now be disconnected at the Inverter and at the Motor / Generator. Inspect AC cable connector and AC connector at the Motor Generator for moisture or contamination.

Note: If moisture or contamination is found, this is a non-Eaton failure. See OEM for repair direction. - Measure the resistance at the AC Cable between the following Pins:

- Pin A to Cable Shield

- Pin B to Cable Shield

- Pin C to Cable Shield

- If resistance reading is “OL”, remeasure the AC cable on the inverter side.

- If resistance among any AC connector pin to Cable Shield in is OL, go to Step 4.

- If any resistance/continuity is found replace OEM supplied AC Cable, go to Step 4.

STEP 4. Measure the resistance of each phase within the Motor / Generator to case.

- If you are coming here from Step 3 a high voltage shutdown procedure should have already been performed and the key has been turned off. If this has been completed continue to # 2.

Danger: See High-Voltage Service Shutdown and Power-Up Procedures. Follow the procedures to avoid shock, burn or death from improperly handled high-voltage. - If you are coming here from Step 1 the high voltage AC Cable should be disconnected from the inverter and the Motor / Generator. If steps 1 and 2 have been completed continue to # 3.

- Measure 3-phase sockets at the Motor / Generator.

- Socket A to Motor / Generator case

- Socket B to Motor / Generator case

- Socket C to Motor / Generator case

- If any resistance or continuity is found, replace the Motor/Generator. See the MY09 Motor/Generator Removal and Installation procedure in TRSM2000. After repairs are made, go to Step 11.

- If resistance is OL the Motor / Generator is not shorted to ground, go to Step 11.

STEP 5. Verify the integrity of the High Voltage DC Cable.

- If you are coming here from Step B a high voltage shutdown should have already been performed and the key has been turned off. If this has been completed continue to # 2. If the high voltage shut-down procedure has not performed go back to Step 1.

Danger: See High-Voltage Service Shutdown and Power-Up Procedures. Follow the procedures to avoid shock, burn or death from improperly handled high-voltage. - Disconnect the DC connector from the PEC. The DC connector at the Inverter should not be disconnected. Inspect DC cable connector and DC connector at the PEC for moisture or contamination. If moisture or contamination is found, this is a non-Eaton failure. See OEM for repair direction. If no moisture or contamination is found, proceed to # 3.

- Measure the resistance at the DC Cable between the Positive (+) to Cable Shield and Negative (-) to Cable Shield.

- If resistance is open or OL, go to Step 7.

- If resistance is 0-220K Ohms, go to Step 6.

STEP 6. Verify the integrity of the High Voltage DC Cable.

- If you are coming here from Step E a high voltage shutdown should have already been performed and the key has been turned off. If this has been completed continue to step 2. If the high voltage shut-down procedure has not performed go back to Step 1.

Danger: See High-Voltage Service Shutdown and Power-Up Procedures. Follow the procedures to avoid shock, burn or death from improperly handled high-voltage. - Disconnect the DC connector from the Inverter. The DC cable should be disconnected at the PEC and the Inverter. Inspect DC cable connector and DC connector at the Inverter for moisture or contamination.

Note: If moisture or contamination is found, this is a non-Eaton failure. See OEM for repair direction. - Measure High Voltage DC cable End to End.

- Positive (+) to Positive (+)

- Negative (-) to Negative (-)

- Positive (+) to Shield Ground

- Negative (-) to Shield Ground

- If resistance is OL, go to Step 7.

- If resistance is anything other than OL replace the High Voltage DC cable. After repairs are made, go to Step 11.

STEP 7. Verify the integrity of the Inverter.

- If you are coming here from Step F a high voltage shutdown should have already been performed and the key has been turned off. If this has been completed continue to step 2. If the high voltage shutdown procedure has not performed go back to Step 1.

Danger: See High-Voltage Service Shutdown and Power-Up Procedures. Follow the procedures to avoid shock, burn or death from improperly handled high-voltage. - Measure the resistance within the Inverter positive to Case (Ground) on the Inverter High Voltage pins on the DC side.

- Positive (+) to Inverter Case

- Negative (-) to Inverter Case

- If open or OL, go to Step 8.

- If resistance is 0-220K Ohms, replace the Inverter. After repairs are made,

go to Step 11.

STEP 7. Verify the integrity of the Inverter.

- If you are coming here from Step 6 a high voltage shutdown should have already been performed and the key has been turned off. If this has been completed continue to # 2. If the high voltage shutdown procedure has not performed go back to Step 1.

Danger: See High-Voltage Service Shutdown and Power-Up Procedures. Follow the procedures to avoid shock, burn or death from improperly handled high-voltage. - Measure the resistance within the Inverter positive to Case (Ground) on the Inverter High Voltage pins on the DC side.

- Positive (+) to Inverter Case

- Negative (-) to Inverter Case

- If open or OL, go to Step 8.

- If resistance is 0-220K Ohms, replace the Inverter. After repairs are made,

go to Step 11.

STEP 8. Verify components.

- If you are coming here from Step 7 a high voltage shutdown should have already been performed and the key has been turned off. If the high voltage shutdown procedure has not performed go back to Step 1.

Danger: See High-Voltage Service Shutdown and Power-Up Procedures. Follow the procedures to avoid shock, burn or death from improperly handled high-voltage. - Verify unit is supplied with DC/DC Converter.

- If equipped with a DC/DC Converter, go to Step 9.

- If no DC/DC Converter found see MY09 Power Electric Carrier (PEC) Removal and Installation procedure in TRSM2000 and perform repairs, then go to Step 11.

STEP 9. Verify integrity of the High Voltage DC/DC cable between the PEC and the DC/DC converter.

- If you are coming here from Step H a High Voltage shutdown should have already been performed and the key has been turned off. If the high voltage shutdown procedure has not performed go back to Step 1.

Danger: See High-Voltage Service Shutdown and Power-Up Procedures. Follow the procedures to avoid shock, burn or death from improperly handled high-voltage. - Disconnect the DC/DC High-Voltage Cable at the PEC.

- Measure the resistance to ground at the DC Cable Connector on both the positive and negative terminals to shield:

- Positive (+) to Cable Shield

- Negative (-) to Cable Shield

- If any resistance is between 0-220K Ohms, go to Step 10.

- If resistance is OL, replace the PEC, then go to Step 11.

STEP 10. Verify the integrity of the High Voltage DC/DC cable between the PEC and the DC/DC Converter.

- If you are coming here from Step I a high voltage shutdown should have already been performed and the key has been turned off. If the high voltage shutdown procedure has not performed go back to Step 1.

Danger: See High-Voltage Service Shutdown and Power-Up Procedures. Follow the procedures to avoid shock, burn or death from improperly handled high-voltage. - Disconnect the DC/DC High-Voltage Cable at the DC/DC Converter. The High Voltage DC Cable should be disconnected from the PEC and the DC/DC Converter.

- Measure resistance on DC/DC Cable.

- Positive (+) to positive (+)

- Negative (-) to negative (-)

- Positive (+) to shield ground

- Negative (-) to shield ground

- Measure resistance at the inverter

- Positive (+) to DC/DC case

- Negative (-) to DC/DC case

- If resistance is OL, find error in testing, go to Step 9.

- If resistance is anything other than OL, replace DC/DC Converter, then go to Step 11.

STEP 11. Verify repair.

- Key on.

- Clear codes, see Clear Inactive Faults.

- Drive the vehicle and attempt to reset the code.

- Check for codes, see View Active and Inactive Faults.

- If no codes, test is complete.

- If fault Code 107 appears, find error in testing, go to Step 1.

- If a code other than 107 appears, see Fault Code Index List.

Any transmission part you need we have it! Same day shipping available, worldwide.

NEED FREE SUPPORT FROM ONE OF OUR EXPERTS?