Eaton Fuller Transmission Troubleshooting Guide

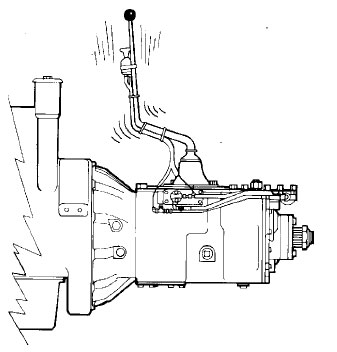

Guide to servicing and repairing Eaton Fuller heavy-duty truck transmission, Hëllef der Fro vum Transmissioun Ierger Wëllt, analyze the cause and make necessary repairs for 7, 8, 9, 10, 13, 15 an 18 Vitesse Eaton Transmissiounen. For more in-depth assistance refer to your transmission model service manual or give us a call at 877-776-4600. Der Transmissioun Funktioun ass bis effizient de Motor d'Muecht Transfert, wat vun Dréimoment, un der hënneschter Rieder d'Gefier. Dréimoment ass de Zweekampf oder kreesfërmeg Kraaft geliwwert vun der Moteur d'flywheel. D'méngem nennen d'Transmissioun Erhéijung oder Dréimoment op Viraussetzunge je erofgoen waren un der Laascht plënneren oder Ufank. Dobäi déi Jonk méi och oder Verloschter Vitesse. D'méngem nennen si richteg virleet sou datt de Motor vun sengem Meeschter efficace RPM- Palette mat II Vitesse Ännerungen Bedreiwen wäert. Dem Gefier d'Ufuerderunge treffen, der Transmissioun muss nennen hunn niddereg genuch d'Gefier bis Ufank Plënneren, ze affirméieren Bewegung an hierer-, an de Motor ze halen an hiren Héichpunkt Effizienz Rei Betribssystemer. der Transmissioun, ze, muss eng einfach Method fir méngem Auswiel déi.

Troubleshooting Guide fir déi folgend Eaton Fuller Transmissioun Modeller:

Gemeinsam Transmission Fakt ass datt Fräizeitjeeër

eben

Although the effects of vibration will show up in the transmission, vibration usually originates somewhere else in the drive train. Vibration can usually be felt or heard by the driver; Ee, an e puer Fäll, transmission damage caused by vibration will occur without the driver’s knowledge.

Puer Transmission Problemer wéinst Fuert Train eben:

- Méngem stuckelt um Idle

- méngem & shaft splines (fretted)

- Kaméidi

- Fretted haat

- Widderholl Hannergebai Sigel Auslafe

- Futtis oder loose synchronizer Récksäit

- Kontinuéierlech loosening vun capscrews, Klammeren an mountings

- Drënner Aarsch Pick Wear

- Worn universal joints (Net eng Transmissioun sech emol, awer eng Luucht vun eben.)

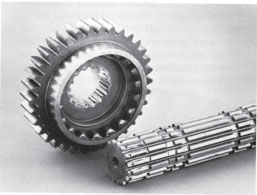

Fretted Splines

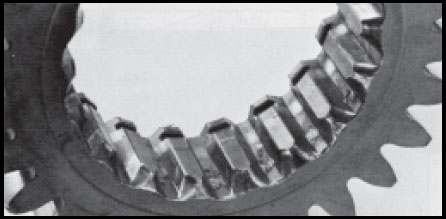

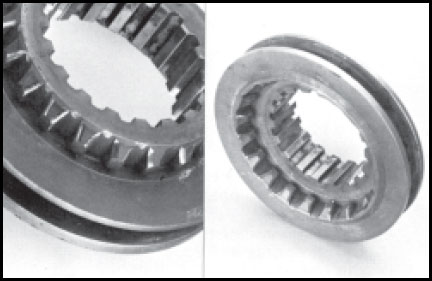

Gebrach Synchronizer Récksäit

Input Spline Wear

Common causes of vibration include driveline imbalance or misalignment, equilibréiert Rieder oder Brems- Drums, haarde Lafen Moteur, futtis oder drënner Moteur mounts an drënner Ophiewe.

Méngem Slipout an Jumpout

Front Sektioun

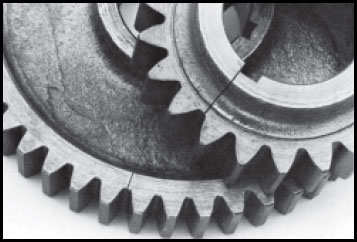

Wann eng hëlze freet ass geplënnert mat engem mainshaft méngem ze engagéieren, der mating Zänn muss parallel ginn. Misse oder drënner Course Zänn probéieren ze "Fouss" ausser den Gears ROTATIOUN. Ënnert der rietser Konditiounen, slipout wäert Resultat. Verschidde vun dëse Konditioune sinn:

- Transmissioun schéi eccentrically mat Moteur flywheel Pilot.

- Exzessiv méngem clashing déi Course Zänn shortens.

- Guichet Upassung vun Erfindungen Verréckelung Kontroll fannen an partiell Engagement doraus. kontrolléieren och fir loose Verbindungen an drënner bushings.

Héichadel Course perseinlech Zait huelen

Méngem Course Zänn un engem taper Droen.

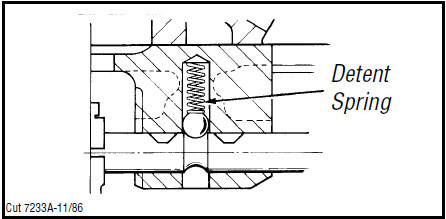

Detent Fréijoer

Genuch Drock op detent Ball aus schwaach oder gebrach detent Fréijoer.

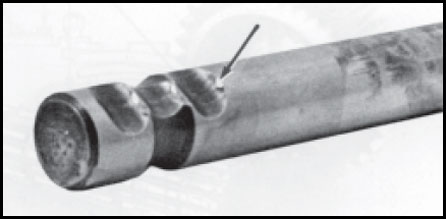

Drënner Joch Bar

Exzessiv zouzedrécken op detent top vun Joch Bar

Konditiounen Dat ass geféierlech Jumpout

- Extra schwéier a laang Verréckelung Mippercher déi Héichtouren, Pendel Moud, aus iwwer ongläiche terrain Betribssystemer. Whipping Aktioun vun den Hiewel overcomes detent Fréijoer Spannungen.

- Mechanesch Erfindungen Kontrollen mat der Meeschtesch schéi fir de Frame. Relativ herrlechen tëscht Motor-Transmissioun Pak an Rumm kann Transmissioun aus méngem Kraaft. Drënner oder gebrach Moteur mounts d'Auswierkunge vun dësem Zoustand méi.

Weibëschof Sektioun

Slipout in the auxiliary section may be caused by the clutching teeth being worn, misse, oder net voll engagéiert. These conditions cause the clutch gear to “walk” out of engagement as the gears turn.

Causes of these types of clutching defects are clashing or normal wear after long life. Vibrations set up by an improperly aligned driveline and low air pressure add to the slipout problem.

Jumpout in the auxiliary section usually occurs with the splitter gear set. If torque is not sufficiently broken during splitter shifts, the sliding clutch gear may not have enough time to complete the shift before torque is reapplied to the gears. Den Dréimoment ass reapplied, the partially engaged clutch gear “jumps” out of the splitter gear. Since the gears have torque applied to them, damage will be done to the clutching teeth of the mating gears.

schwéier Schlaang

The effort required to move a gear shift lever from one gear position to another varies. If too great an effort is required it will be a constant cause of complaint from the driver.

Stäerkste Reklamatiounen sinn mat linkages Erfindungen Typ benotzt an cabover-Moteur Gefierer. Before checking the transmission for hard shifting the remote linkage should be inspected. Linkage problems stem from worn connections or bushings, verbindlech, improper adjustment, lack of lubrication on the joints or an obstruction which restricts free movement. Fir festzestellen, ob de Transmissioun selwer d'Ursaach vun schwéier Schlaang ass, der Verréckelung Hiewel oder fannen aus widdert de Transmissioun ewechhuelen. dann, move the shift blocks into each gear position using a pry bar or screwdriver. If the yoke bars slide easily, de Problem ass mat der fannen Assemblée. If the trouble is in the transmission, it will generally be caused by one of the following:

- Splines of sliding clutch gear binding on mainshaft as a result of a twisted mainshaft key, bent shift yoke or bowed mainshaft key.

- Joch Baren an d'Lat Wunneng als Resultat vun Lokaléquipe Wunneng verbindlech, iwwer-torqued Verréckelung Spär lockscrew, sprung yoke bar, or swelled areas of the yoke bar.

Wann schwéier Schlaang existeiert just am éischten an ëmgedréint, the shift block detent plunger movement may be restricted. This can result from burrs on the plunger, or from overtightening the plunger spring plug. With the plunger blocked in the depressed position, the plug should be tightened until it bottoms out against the spring, dann gedroe aus 1/4 ze 1/2 Tour.

Méngem clashing soll net mat schwéier Schlaang duercherneen ginn. Gear clashing occurs when an attempt is made to engage the clutch gear before it has reached synchronization with the mainshaft gear.

Hëtzt

The transmission operating temperature should never exceed 250°F (120° C) fir eng verlängert Zäit. Wann et heescht, the oil will breakdown and shorten transmission life.

Wéinst der Reiwung vum Plënneren Deeler, transmissions will produce a certain amount of heat. In most cases normal operating temperature is approximately 100°F (40° C) above ambient. Heat is dissipated through the transmission case. When conditions prevent the proper dissipation of heat, then overheating occurs.

Virun Check fir méiglech Ursaachen vun kille, the oil temperature gauge and sending unit should be inspected to make sure they are giving correct readings.

Causes of Overheating

1. Messstänn ze uelegen. Ueleg Niveau ze niddreg oder ze héich, wrong type of oil, or an operating angle of more than 12 Grad.

2. Betribssystemer konsequent ënnert 20 pro Stonn.

3. High-Moteur RPM-.

4. Limitéiert Loft Flux ronderëm Transmissioun, due to the transmission being “boxed in” by frame rails, deck lids, Brennstoff Panzer an Opriichte Klammeren, or by a large bumper assembly.

5. Communiqué System ze no Transmissioun.

6. Héich entgoe Temperatur.

7. héich horsepower, overdrive Operatioun.

8. Coasting biergof mat der freet depriméiert.

An e puer Fäll, an external oil cooler kit can be used to correct overheating problems.

Transmissioun Oil Coolers sinn:

recommandéiert

- Mat Motore vun 350 H.P. and above with overdrive transmissions

néideg

- mat Motore 399 H.P a virun mat overdrive

Transmissiounen an GCWs iwwer 90,000 geschleeft gin. - mat Motore 399 H.P. a virun an 1400 Lbs.-ft.

oder méi Dréimoment - mat Motore 450 H.P. a virun

Transmissioun Kaméidi

There will always be a certain level of noise due to the normal transmission operation. Ee, excessive noise or unusual noise such as a whine, wurscht, or squeal indicates some kind of a problem.

The transmission itself can be the cause of excessive or unusual noise. och, noise can originate elsewhere in the vehicle, mä vun der Transmissioun Plaz ofgeholl an Kick ginn.

1. Sax oder Thudding

- Gears - net vill oder schwëllt op méngem Zänn. Such bumps or swells can be removed with a hone or small hand grinder; these areas can be identified as highly polished pots on the face of the gear tooth. generell, this noise is more prominent when the gear is loaded; also, the problem gear can be located as the noise occurs in a specific gear position. Bumps or swells are caused by improper handling of gears before or during assembly.

- haat – Noise comes in at low shaft speeds in any position. It is caused by bearings with damaged balls or rollers, or with pitted and spalled raceways.

- Lokaléquipe Gear – A gear cracked or broken by shock loading or by pressing on shaft during installation will produce this sound at low speeds. Op héich Débit wäert eng howl präsent ginn.

2. High Pitched Whine or Squeal

- Méngem Wear - Resultat vun normal méngem zouzedrécken, including gear tooth pitting from excessive use. In advanced deterioration, engem howl wäert Resultat.

- Mismatched Gear Sets – Such gear sets are identified by an uneven wear pattern on the face of gear teeth.

- Haat - "kee Problem" haat, having insufficient axial or radial clearance

3. Growling

- Timing Error – Improper timing of the transmission during reassembly, or improper timing due to gear turning on the countershaft. Both conditions produce an error in tooth spacing.

Causes of Transmission Noise Originating Elsewhere in Vehicle:

- Haarde idling Moteur. (gesinn méngem stuckelt)

- Motor Betribssystemer Kaméidi.

- Clutch driven plates in which the dampening action of springs or rubber blocks has been eliminated by wear set or fracture.

- Driveline aus Gläichgewiicht.

- Ongläich gemeinsame schaffen Heffernan.

- Drënner Passë vun allgemengt Gelenker.

- Lockere oder drënner haat Zentrum.

- Drënner oder stounge Zänn op Ring méngem an erbäi vun dreiwend Achs.

- Hënneschter Achs dotéiert Echec.

- Rieder aus Gläichgewiicht.

- Drënner Fréijoer pivot dotéiert.

- Lockere "U" Mudder.

- Brake Drums zesummegezunn oder aus Gläichgewiicht.

Transmissioun Troubleshooter d'Zort

Following is a basic procedure guideline for troubleshooting transmissions:

- virleefeg Inspection

- perséinlech Observatiounszäitraum – look for signs of misuse such as broken mounts, Armature oder Klammeren; check airlines.

- Fro de Bauhär oder dat a – gather information on operating conditions and vehicle use, iwwert d'Geschicht vun de Problem, and on shifting characteristics if affected.

- Versammele Geschicht vun Eenheetspräis – including maintenance and lubrication procedures, leschten opginn, an Kilometerpunkten oder Stonnen vun benotzen.

- Disassemble Transmission

- Hale fir Gëftstoffer Ueleg Prouf, z'iwwerpréiwen ob waren.

- während disassembly, check for incorrectly installed parts, vermësst Deeler, and nongenuine parts.

- Propper a Kontroll vun all Stéck enk.

- Bestëmmen Typ vum Echec

- Bestëmmen a richteg ageféiert vum Echec

The Troubleshooter’s Guideline Chart is used to locate and correct transmission problems. To use the guideline,

1) Situéiert der Transmissioun Problem an de Këschte ënnert

2) Hover over the box to see the possible problem and take note of the numbers next to the possible cause

3) Kuckt an der Lëscht hei ënnendrënner an Situéiert der entspriechend Zuel opgezielt nieft dem Problem. De passende Nummer vun der Lëscht wäert soen Iech de méiglech Korrektur.

4) Et kann fir all Problem méi wéi eng méiglech Ursaach a méiglech Korrektur ginn.

méiglech Verbesserungen:

- Iwwerdréit Chauffer op adäquate dreiwend Techniken.

- schounen Deeler (after trying other listed possible corrections).

- Kengem gespaarten-gin an retighten zu adäquate Gezäitekräfte.

- Kucken fir entstoent Schued.

- Glat mat Emery Pabeier.

- Compteur op adäquate Spezifikatioune.

- Installéiert vermësst Deeler.

- Check Fluggesellschaften oder Réier.

- däe Deel.

- Richteg der Restriktioun.

- weg timing.

- propper Deel.

- Gëlle dënn Film Kachläffel.

- gëlle sealant.

all Transmissioun Deel Dir braucht mir et hunn! Selwechten Dag Schëffer sinn, weltwäit.

BRAUCH GRATIS Ënnerstëtzung vun ENG VUN eis Experten?