Eaton Fuller nifşek Guide Pirsgirêkan

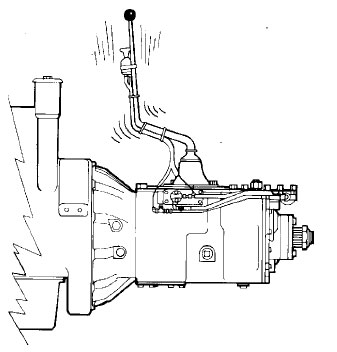

Guide to servicing and repairing Eaton Fuller heavy-duty truck transmission, alîkariya cihên ku pirsgirêka teng de ji nifşekî, analyze the cause and make necessary repairs for 7, 8, 9, 10, 13, 15 û 18 lezkirin transmissions Eaton. For more in-depth assistance refer to your transmission model service manual or give us a call at 877-776-4600. Fonksîyona Veguhestina e ji bo baþtir hêza engine ya veguhestina, di warê torque, ji bo wheels rear de wesayiteke ya. Torque çivanebûn an hêzeke bezandin destê flywheel li engine ye. rêjeyên gear Veguhestina zêde bikin an jî wê kêm torque li gor pêdiviyên pêwîst ji bo bar an dest bi load. Xusro jî zêde dibe an leza xwe kêm dike. Rêjeyên gear bi awayekî rast di bernameya da ku engine li range RPM efektîv wê ya herî bi Guherandinên speed pêşverû kar ê. Ji bo ku daxwazên de wesayiteke ya, vitêsê divê rêjeyên bes kêm ji bo ku dest bi wesayîta Kurdayetiyê heye, bo domandina tevgera up-notên, û bihêlin, engine li range berhênandariya di asta xwe ya. Veguhestina, jî, divê rêbaza ku bi hêsanî ji bo hilbijartinę de gear ne.

Guide Pirsgirêkan ji bo modelan de ji nifşekî Eaton Fuller jêr:

Gazin, ji nifşek a Common

Vibration

Although the effects of vibration will show up in the transmission, vibration usually originates somewhere else in the drive train. Vibration can usually be felt or heard by the driver; lebê, Di hin rewşan de, transmission damage caused by vibration will occur without the driver’s knowledge.

De hin pirsgirêkên me nifşek ji ber Drive Train Vibration:

- ponij û Gear de hate pûç

- Gêr & shaft splines (nanxwarina)

- Deng

- Bearings nanxwarina

- Dubare kir ku nehêle mora rear

- pin synchronizer Broken an vebûn

- xavbûna Continuous ji capscrews, bixemilînî û mountings

- Westiyam, Shaft Spine Wear

- Worn universal joints (Ne ji nîşanên transmission, di heman demê de nîşana vibration.)

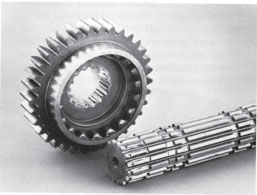

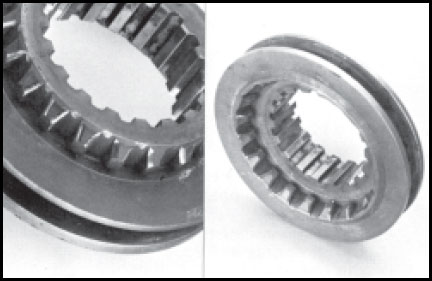

Splines nanxwarina

Pin Synchronizer Broken

Input Spline Wear

Common causes of vibration include driveline imbalance or misalignment, wheels an çermikên şikand bêhevseng, engine asê running, heywanan engine şikestî an westiyam, û cemidandina westiyam,.

Gear Slipout û Jumpout

Beþ Front

Dema ku zilamê de, dişemite meşî ye ku bi mentiqekî bi gear mainshaft, diranên mating li hev bin. diranên clutching Tapered an westiyam, daxwaza "meşa" hewl bidin bêyî ku vitêsê cihê. Di bin şert û mercên mafê, slipout bi encam bibe. Hin ji van şert û mercên ne:

- Nifşek eccentrically bi pîlotê flywheel engine siyar.

- dikete gear Excessive ku têrbiryar diranên clutching.

- sererastkirinê yên xelet ji têkiliya kontrol guherîna ji dûr ve di encamê de bi pabendbûna bi qismî. Jî ji bo girêdana vekin û bushings westiyam, kontrol.

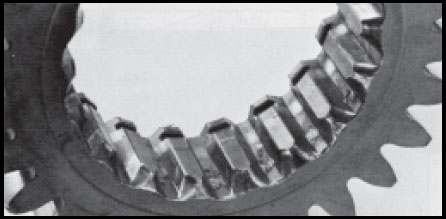

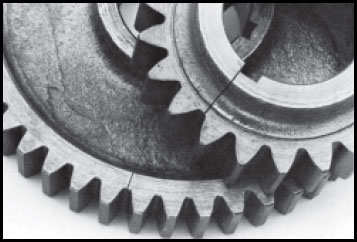

Teeth Clutching xeyidî

Gear clutching diranên wearing ji bo taper.

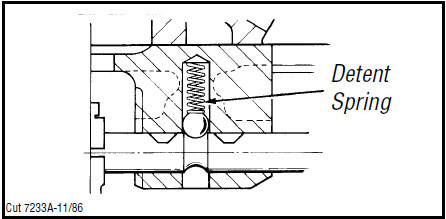

Detent Spring

zext e Têrê li ball detent ji biharê detent qels an şikandin.

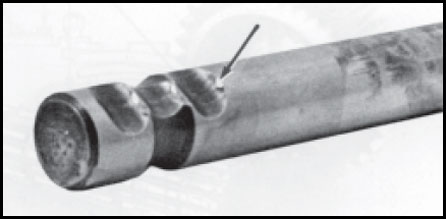

Worn nîrê Bar

wear Excessive li ser asta detent ji bar nîrê

Şert û mercên ku dikare Jumpout Sedama

- Extra levers guherîna giran û dirêj ku deydîkê, fashion bêhêviyan, ji xebatê yên li ser vehewandina lawaz e. action kûrkirina ji lever bi ser dikeve detent tengezarî biharê.

- kontrola ji dûr ve mekanîk, bi axayê siwarî ji frame. tevgera Dengûbasên di navbera pakêta engine-belavkirin û frame dikarin ji nifşekî ji gear zorê. Westiyam, an jî heywanan engine şikestî zêdekirina bandora vê rewşa.

Beþ auxiliary

Slipout in the auxiliary section may be caused by the clutching teeth being worn, tapered, an bi çalakî ne. These conditions cause the clutch gear to “walk” out of engagement as the gears turn.

Causes of these types of clutching defects are clashing or normal wear after long life. Vibrations set up by an improperly aligned driveline and low air pressure add to the slipout problem.

Jumpout in the auxiliary section usually occurs with the splitter gear set. If torque is not sufficiently broken during splitter shifts, the sliding clutch gear may not have enough time to complete the shift before torque is reapplied to the gears. Wek torque reapplied ye, the partially engaged clutch gear “jumps” out of the splitter gear. Since the gears have torque applied to them, damage will be done to the clutching teeth of the mating gears.

GUHERTINA Hard

The effort required to move a gear shift lever from one gear position to another varies. If too great an effort is required it will be a constant cause of complaint from the driver.

Gelek gilî û bi hêztir bike type ji dûr ve hatine bikaranîn, di wesayîtên cabover-engine in. Before checking the transmission for hard shifting the remote linkage should be inspected. Linkage problems stem from worn connections or bushings, girêdidan, improper adjustment, lack of lubrication on the joints or an obstruction which restricts free movement. Ji bo destnîşankirina eger ji nifşekî bi xwe doza ji reel zehmet e, jê lever Shift an jî çênekin ji ser depika ser serê vitêsê. Paşan, move the shift blocks into each gear position using a pry bar or screwdriver. If the yoke bars slide easily, di tengahiyê de ye, bi meclîsa têkiliya. If the trouble is in the transmission, it will generally be caused by one of the following:

- Splines of sliding clutch gear binding on mainshaft as a result of a twisted mainshaft key, bent shift yoke or bowed mainshaft key.

- darikên nîrê mulzem in xanî bar ya ku di encama xanî bibun, ser-torqued lockscrew block guherîna, sprung yoke bar, or swelled areas of the yoke bar.

Ger diguherîn zehmet tenê di yekem û berevajî diqewime, the shift block detent plunger movement may be restricted. This can result from burrs on the plunger, or from overtightening the plunger spring plug. With the plunger blocked in the depressed position, the plug should be tightened until it bottoms out against the spring, piştre bi piştgirîya derve 1/4 ber 1/2 zîvir.

dikete Gear divê bi guherandina zehmet tevlihev ne. Gear clashing occurs when an attempt is made to engage the clutch gear before it has reached synchronization with the mainshaft gear.

Germa

The transmission operating temperature should never exceed 250°F (120° C) bo demeke dirêj ji dem. Ger ev, the oil will breakdown and shorten transmission life.

Ji ber yên ku pirsgirêkên ciddî yên parçeyên, transmissions will produce a certain amount of heat. In most cases normal operating temperature is approximately 100°F (40° C) above ambient. Heat is dissipated through the transmission case. When conditions prevent the proper dissipation of heat, then overheating occurs.

Berî muayene ji bo sedemên ku yên pir, the oil temperature gauge and sending unit should be inspected to make sure they are giving correct readings.

Causes of Overheating

1. gêl de vediqetîne. asta petrolê kêm an jî zêde bilind, wrong type of oil, or an operating angle of more than 12 dereceyên.

2. Kar bi lehev bê bin 20 MPH.

3. RPM engine High.

4. herikîna hewa sînorkirin, li dora ji nifşekî, due to the transmission being “boxed in” by frame rails, deck lids, tankên sotemeniyê û bixemilînî bi heybet, or by a large bumper assembly.

5. sîstema Exhaust jî nêzî ji nifşekî.

6. germahîya ambient High.

7. bergîrî High, operasyona overdrive.

8. Coasting Downhill bi destê zilamê bînteng.

Di hin rewşan de, an external oil cooler kit can be used to correct overheating problems.

Nifşek û bihayên petrolê in:

Baştir e

- Bi motorên ji 350 H.P. and above with overdrive transmissions

pêwîst

- bi motorên 399 H.P û li jor bi overdrive

transmissions û GCWs ser 90,000 lbs. - bi motorên 399 H.P. û li jor û 1400 Lbs.-Ft.

an torque mezintir - bi motorên 450 H.P. û jor

Noise nifşek

There will always be a certain level of noise due to the normal transmission operation. Lebê, excessive noise or unusual noise such as a whine, qûrqûrkirin, or squeal indicates some kind of a problem.

The transmission itself can be the cause of excessive or unusual noise. Jî, noise can originate elsewhere in the vehicle, lê bê hildan û bergirî ji aliyê vitêsê.

1. Li derî bixin an zingînî

- Gears - Untitled an çêrê li diranên gear. Such bumps or swells can be removed with a hone or small hand grinder; these areas can be identified as highly polished pots on the face of the gear tooth. Giştîve, this noise is more prominent when the gear is loaded; ji ber vê yekê, the problem gear can be located as the noise occurs in a specific gear position. Bumps or swells are caused by improper handling of gears before or during assembly.

- Dordîtinî – Noise comes in at low shaft speeds in any position. It is caused by bearings with damaged balls or rollers, or with pitted and spalled raceways.

- Cracked Gear – A gear cracked or broken by shock loading or by pressing on shaft during installation will produce this sound at low speeds. Li qapat a hewarê wê amade bibe.

2. High Pitched Whine or Squeal

- Wear Gear - Di encama wear gear normal, including gear tooth pitting from excessive use. In advanced deterioration, a hewarê encama wê.

- Mismatched Gear Sets – Such gear sets are identified by an uneven wear pattern on the face of gear teeth.

- Bearings - bearings "tertikek", having insufficient axial or radial clearance

3. seyan

- Timing Error – Improper timing of the transmission during reassembly, or improper timing due to gear turning on the countershaft. Both conditions produce an error in tooth spacing.

Causes of Transmission Noise Originating Elsewhere in Vehicle:

- engine idling Rough. (dîtina ponij û gear)

- dengî xebatê Engine.

- Clutch driven plates in which the dampening action of springs or rubber blocks has been eliminated by wear set or fracture.

- Driveline ji balance.

- angles kar hevbeş ya newekhev.

- xaç û bêhalin, li movik gerdûnî.

- bearings navenda Loose an westiyam,.

- diranên westiyam, an Ezdî li gear ring û pinion ji axle driving.

- têkçûna wan çêbibin axle Rear.

- Wheels ji balance.

- biharê Worn Hilgirtina pivot.

- Loose "U" ji jor.

- çermikên Brake warped an ji balance.

Rênîşanderek ji nifşek a Troubleshooter da

Following is a basic procedure guideline for troubleshooting transmissions:

- pêşîn

- Observation şexsî – look for signs of misuse such as broken mounts, cîh an bixemilînî; check airlines.

- Jêpirsîn ji Xwedîyê an Operator – gather information on operating conditions and vehicle use, li ser dîroka pirsgirêka, and on shifting characteristics if affected.

- Bicivin, History of Unit – including maintenance and lubrication procedures, şkestin borî, û mileage an saet ji bikaranîna.

- nifşek Disassemble

- Keep test petrolê ji bo ÿgir, Heke pêwîst.

- di dema disassembly, check for incorrectly installed parts, parçeyên wenda, and nongenuine parts.

- Paqij û vêkolîna her perçek ji nêz ve.

- Diyar Type of Têkçû

- Diyar bike û doza rast ji Têkçû

The Troubleshooter’s Guideline Chart is used to locate and correct transmission problems. To use the guideline,

1) Locate pirsgirêka veguhestinê li jêrîn bitikînin

2) Hover over the box to see the possible problem and take note of the numbers next to the possible cause

3) ji bo li lîsteya jêr binihêrin û cihê ku hejmara têkildar re rêyên din ji bo pirsgirêka. Hejmara hevcotî ji lîsteya wê tu correction gengaz re dibêjim.

4) Dibe ku zêdetir ji yek doza gengaz û correction ji bo her pirsgirêkeke hene.

serastkirin gengaz:

- Telîmatdayîna driver li ser teknîkên ajotinê proper.

- Replace perçeyên (after trying other listed possible corrections).

- Laç'ika lock-jîn û retighten bo torque proper.

- ji bo zirar dawî binêrin.

- Bikes bi paper emery.

- Reset ji taybetmendyên proper.

- Install beşên wenda.

- Check airlines an xortimên.

- Bi şidandina part.

- Lê agadar sînordarkirina.

- bareyê vevêre.

- part Clean.

- Apply silicone film tenik.

- Apply derzê.

Herçiyek beşek ji nifşekî hûn divê em jî heye! heman rojê di shipping License de, cîhanê.

Bi piştgirîya ji ji pisporên?