Driveline Pirsgirêkan Angularity

perî Vibration

Dinêre Driveline U-Joint Operation Angles

Di çalakiyê de ji a driveline bi hevbeş gerdûnî de hate guherandin yan jî dawiya xebatê de bi rêya results aliyî di motion nerêzî. The driveline wê lezkirin û hêdîtir dikit du caran ji bo her şoreşê. Eger lîstên kar li butona dawiya mîlî ya newekhev in, results vibration perî. Ev vibration perî sempatiya wê ji bo xwe betal derve eger herdu lîstên karê hevbeş de wekhev in.

Cureyên Noise

Noise an vibration ku bi tenê li Leza rê hin jî pêk tê û kêm weke leza zêdebûna giştî ji aliyê angles xebat- jî movik driveline ji ber. Noise an vibration e ku persistent li seranserê cur bi lez û li sewiyê de bi guhertina speed jî diguhure dibe ku ji aliyê drivelines di mijara sedema, çermikên şikand bêhevseng yan discs, an drivelines bi movik gerdûnî ji qonaxa.

Checks DESTPÊKÊ

Make kontrolên yên li jêr, beriya ku bi xwendina angle:

- Check companion flange or yoke nut for looseness and torque to proper specification if necessary.

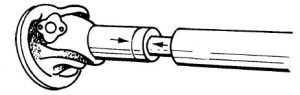

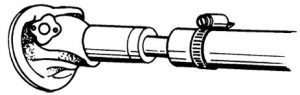

- Driveline slip joints that do not have the arrows or other markings pointing to each other will result in the driveline universal joints being out of phase. Bi gotineke din, the transmission universal joint may be turned one spline or more to the right or left of being aligned with the universal joint at the opposite end of the driveline.

- Some computer designed drivelines are purposely built with U-joints out of phase. Check manufacturer’s specifications for proper setting. Jî, check closely to make certain no twist has occurred to the tubing, causing these two joints to be out of phase Make sure the slip joint works freely and is not bound or seized. Slip joints must absorb axle housing movements.

- Unbalanced drivelines can cause vibration that occurs throughout the speed range of vehicle and varies in intensity with a change of speed. The driveline may be at fault in respect to balance and concentricity. A quick field check to determine driveline balance can be made by securing a small piece of metal or similar weight with a hose clamp to the front of the tube where the splined shaft is welded. Road test the vehicle and continue to move the weight around the tube until the balance point is found and vibration disappears or is minimized.

Drivelines bi dînamîk velocity rotational ye, lewma wan a hevseng û ne ji bo Leza ji her demê ra. Ji ber vê yekê, vibration can be expected when this rotational velocity is exceeded. Check concentricity of driveline by mounting on lathe centers and dial indicating. Check taybetmendîyekî manufacturer ji bo alîkariya runout. - piştgiriya Engine ku westiyam, bi, şikestî an jî vekin, and mounting pads that are worn or deteriorated must be corrected to restore the engine suspension to its original vibration tolerance.

Esasgirtina Readings

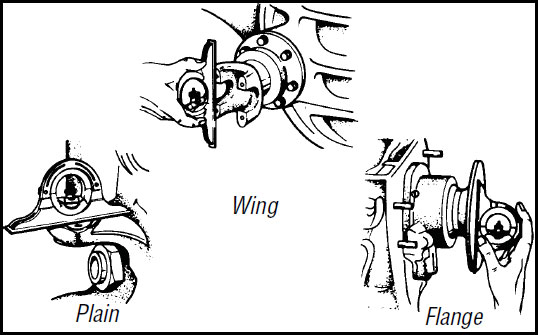

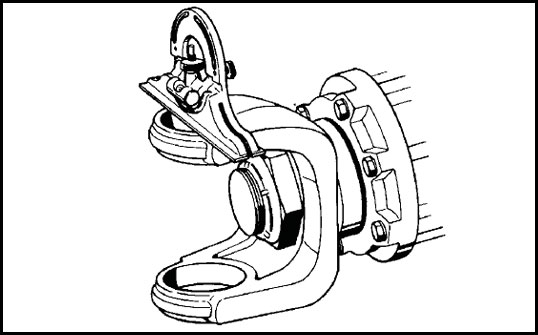

Take readings with protractor from machined surfaces of yokes or companion flanges. Adî, baskê an type flange movik dibe ku rastî. Some will require partial disassembly to obtain accurate readings.

Li ser movik type deşta, it may be necessary to remove the bearing cap. Dema ku mirov bi xwendina, make sure the universal joint is in a vertical plane. At the rear axle, take readings from a machined surface differential carrier that is in the same plane as the axle pinion shaft, an ji surface machined e ku biserêxwe, ji bo mîlî pinion, li kîjan hêsanîtir e?.

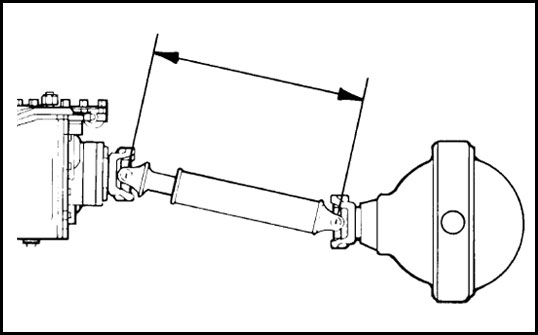

Ger vibration diqewime dema xebatê yên vala, take readings in empty condition. Eger ev yek dema ku barkirin, take readings when loaded. When it is necessary to measure driveline lengths, measure from joint center to joint center

taybetmendîyekî Manufacturer, divê bê şopandin, di dema check angularity destpêkê. Some manufacturers have found it necessary to vary from the ideal due to geometrical limitations. If vibration persists after adhering to manufacturer’s specifications, contact the manufacturer’s representative.

Checks Angularity - Flanges Parallel an Yokes

- Vehicles Single Axle

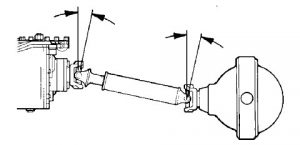

- angle nifşek – Take reading of transmission angle. This angle is the angle to which the rear axle joint angle must match. The transmission angle will have a declination reading of from 0 ber 5 derece di piranîya bûyeran.

- angle axle. Take reading either from machined surface of axle housing or pinion bearing retainer. This angle must be within one degree of the transmission angle.

- Mînak: If transmission angle reading is 3 degrees down to the rear, the rear axle angle should be 3 diplomayên xwe.

- angle nifşek – Take reading of transmission angle. This angle is the angle to which the rear axle joint angle must match. The transmission angle will have a declination reading of from 0 ber 5 derece di piranîya bûyeran.

- Tandem Axles an Vehicles bi Yekîneyên Auxiliary

- Take veguhestina di xwendina angle.

- Take reading from joint of front tandem axle or auxiliary joint. This reading should be within one degree of transmission angle.

- Not: The rear joint of front tandem axle will be the same as the front joint.

- Take xwendina kûrayî hevbeş li axle rear tandem, or axle to rear of auxiliary. This angle must be within one degree of transmission angle.

Sînorên Angle Xebatê ya Joint (Dûberîn)

movik Universal heye hêla kar herî zêde, li gor şêwaz û berhemên. Ev pêşnîyar dikin ku bi kûrayî kar hevbeş ji bo civîna hevbeş paralel di mideyeka ne 8 dereceyên ji bo drivelines sereke li ser 40″ dirêj. Ji bo drivelines sereke di bin 40″ ya herî zêde nabêje divê Length di mideyeka ne (L) dabeş destê 5. (Ev qas têrê nake bo interaxle drivelines.)

Mînak: Ji bo 35″ driveline, the maximum joint working angle would be 35 biserve 5 an 7degrees. This working angle must not be exceeded.

Place protractor on driveline to obtain angle of driveline from transmission to axle. The difference between the driveline angle and the joint angle is the joint working angle. For instance, eger vitêsê 3 diplomayên down, and the driveline angle is down 7 dereceyên, the transmission joint working angle is 7 kêmkir 3 an 4 dereceyên.

Li ser drive tandem an makîneyên auxiliary, take readings in the same manner, comparing the universal joint angles to the driveline angle to which it is attached.

Angularity Checks – Non-Parallel Compensating Angles or Flanges or Yokes

Bi wesayîtên base wheel kurt ku herî kêm length driveline ji zarkî ji bo axle, li driveline pêwîst e ku bi riya angles kar gelekî dijwar li hin makîneyên kar. Ev her weha ji bo interaxle drivelines. Ev kar giran hevbeş lîstên kîvroşkê vibration. To kêm angles kar, li axle ji jor de heta centerline mîlî pinion û ji nifşekî mainshaft midway digihîne centerline di navbera navendên hevbeş Sovîyêt.

Bi Axles drive tandem, the rearward axle is tilted upward until its pinion shaft centerline and forward axle pinion shaft centerline intersect midway between joint centers.

Dema ku hesab ser tesîsên hevpar non-paralel, it is necessary to take the driveline angle readings as well as transmission and axle angle readings.

- Vehicles Single Axle

- Take xwendina rengę transmission

- Take rengę driveline

- Take xwendina rengę hevbeş axle

- To destê, ji bo angles correct:

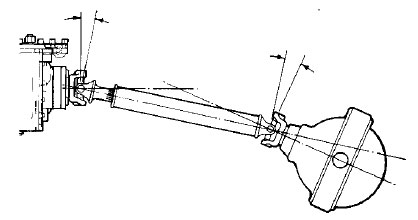

- The difference between the driveline angle and the transmission angle will be the transmission joint working angle.

- The difference between the driveline angle and the axle angle will be the axle joint working angle.

- The two working angles of transmission and axle must be equal.

- Mînak:

nifşek e 3 diplomayên down

Driveline e 7.5 diplomayên down

axle Rear e 12 diplomayên down

Ji ber vê yekê 7.5 kêmkir 3 beramberê 4.5 dereceyên

12 kêmkir 7.5 beramberê 4.5 dereceyên, giving 4.5 equal working angles

- Tandem Axles an Vehicles bi Yekîneyên Auxiliary – When taking readings on tandem drive axles or between auxiliary and rear axle, the same principles apply as with single axle vehicles. Take readings between transmission and front tandem axle, or auxiliary. Take readings between axles or between auxiliary and axle. Bi gotineke din, take angle readings for each set of universal joints

Sînorên Angle Xebatê ya Joint (Non-Parallel)

Pêşniyara me ew e ku herî zêde nabêje kar hevbeş ji bo civînên hevbeş non-paralel dirêjahiya driveline sereke dabeş destê mideyeka ne bêtir ji 10. Bo nimûne, eger length driveline sereke ye 55, ya herî zêde nabêje kar hevbeş e 55 dabeş destê 10 an 5.5 dereceyên. (Ev qas têrê nake bo interaxle drivelines.)

lihevanîna axle

angles Axle dibe ku bi gelemperî ji aliyê yek ji rêyên jêr bê guhertin, li ser corê ji axle.

- Eyar daran torque, eger type adjustable.

- Add to or reduce length of non-adjustable torque rods.

- Add or reduce the number of shims behind torque rod brackets.

- Use correct amount of wedge shims under spring to axle pad.

Cone - Pinion Shaft Angle

Li wir wê bibe yan na, guhertina kûrayî pinion axle bi cureyên Cone ku xwedî tevgera parallelogram. Ev rê, malên differential to move up xwarê û di vertical sererast di dema operasyonê de.

Cone ku ne tevgera parallelogram rê bidin wê mîlî axle pinion bo oscillate di arc, bi vî awayî berdewamî diguherin bi kûrayî mîlî pinion di dema operasyonê de. A mîqdara cida yên vibration dikarin derkevin holê ji ber angles kar ji movik gerdûnî ku momentarily newekhev.

drive Single wesayîtên axle heye guhertina biçûk, yan na ji aliyî axle pinion di dema operasyonê de.

Herçiyek beşek ji nifşekî hûn divê em jî heye! heman rojê di shipping License de, cîhanê.

Bi piştgirîya ji ji pisporên?