Eaton Transmisija Paturot traucējummeklēšana

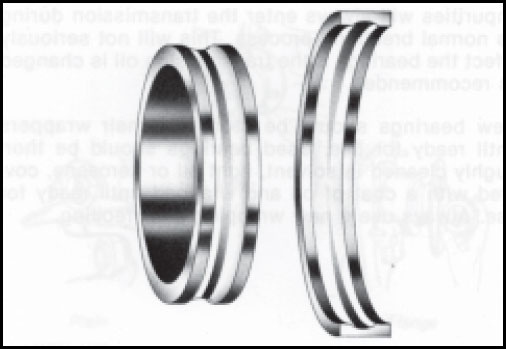

nogurums

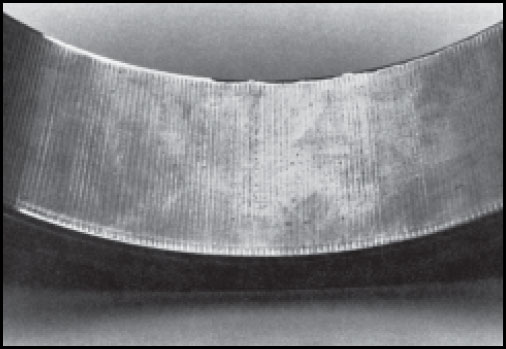

Bearing fatigue is characterized by flaking or spalling of the bearing race. Spalling is the granular weakening of the bearing steel which causes it to flake away from the race. Because of their rough surfaces, spalled bearings will run noisy and produce vibration. Normal fatigue failure occurs when a bearing “lives out” its life expectancy under normal loads and operating conditions. This type of failure is expected and is a result of metal breakdown due to the continual application of speed and load.

Premature fatigue failure may occur in transmissions when the bearing bore is undersized or out of round due to poor quality resleeving. Extreme care should be taken when reboring the housing. Boring the housing off center will result in misalignment of the shafts. Always use precision equipment such as a jig boring machine. Never prick punch the bearing bores to tighten the fit.

Paturot Race "atslāņošanās"

Ball Ceļš Pattern Izraisa out-of-kārtas Squeeze

Eļļošana

Bearing failure due to poor lubrication is characterized by discoloration of the bearing parts, atslāņošanās no rases, un iespējams saplīšana honorārs. Failure may result not only from a low oil level, bet arī no piesārņotas eļļas, improper grade oil, vai sajaucot naftas veidiem (including the use of additives). To prevent this type of failure, the transmission should always be filled to the proper level, using a recommended type and grade of oil, un jāmaina regulāri.

Burnt un Spalled Paturot

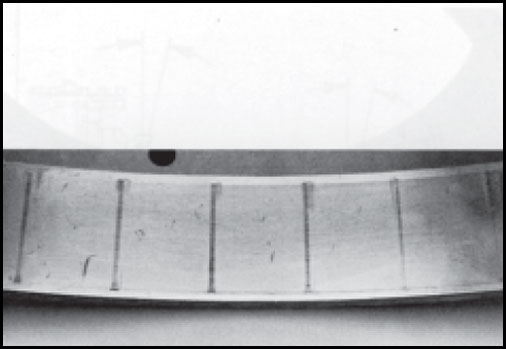

Brinelling

Brinelled Race

Brinelling can be identified as tiny indentations high on the shoulder or in the valley of the bearing raceway. They can be caused by improper bearing installation or removal. Driving or pressing on one race, while supporting the other is the primary cause. To prevent brinelling always support the race which has pressure applied to it. Papildus brinelling, damage can also occur to the bearing shields, retainers and snap rings by using a hammer and chisel to drive bearings.

This damage can be avoided by using correct drivers or pullers.

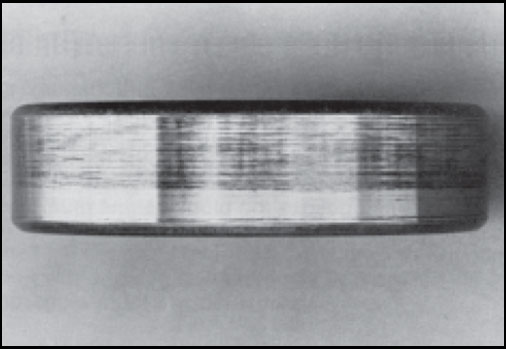

fretting

The bearing outer race can pick up the machining pattern of the bearing bore as a result of vibration. This action is called fretting. Many times a fretted bearing is mistakenly diagnosed as one which has spun in the bore. Only under extreme conditions will a bearing outer race spin in the bore.

Stīgu Ārējais Race

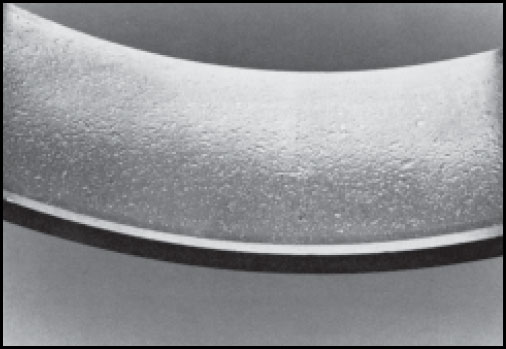

piesārņojums

Piesārņotais Race

Kad gultņi neizdodas, kā rezultātā piesārņojums, it is due to either contaminants entering the transmission case or the bearings have been improperly handled during service or storage. Bearings affected from contamination are identified by scoring, scratching or pitting of the raceways and balls or rollers, or a build-up of rust or corrosion on the bearing parts. Papildus, klātbūtne ļoti sīkām daļiņām eļļā, such as abrasive dust, vai izmantošana pārāk aktīvās EP (galējs spiediens) eļļas, will act as a lapping compound and produce a very highly polished surface on the raceways and balls or rollers. This lapping process will significantly shorten the life of the bearing.

Impurities will always enter the transmission during its normal breathing process. This will not seriously affect the bearings if the transmission oil is changed as recommended. New bearings should be stored in their wrappers until ready for use. Used bearings should be thoroughly cleaned in solvent, vieglās eļļas vai petroleja, covered with a coat of oil and wrapped until ready for use. Always use a new wrapping after reoiling.

novirze

Misalignment can occur in the input shaft drive gear bearing if the transmission is mounted eccentrically with the pilot bearing bore in the flywheel. An indication of this condition would be damage to the ball separators and shield.

Sajūga korpuss, sajūgs korpuss montāžai seja, and pilot bearing should be checked for eccentricity, foreign matter and proper mounting position when trying to locate the cause of the misalignment.

paturot nobīde

elektriskā loka veidošanās

elektriskā loka veidošanās

When an electric current passing through a bearing is broken at the contact surfaces of the ball or roller and races, arcing results, kas būs bedre nesošās daļas. In extreme cases, the balls or rollers may actually be welded to the bearing races, preventing the bearing from rotating. This condition may occur in truck transmissions as a result of electric welding on the truck with an improper ground. When doing either A.C. vai D.C. metināšanas, never place the ground so as to allow current to pass through the transmission.

jebkurš pārraides daļa Jums ir nepieciešams mums tas ir! Tajā pašā dienā kuģniecības pieejams, vispasaules.

NEED FREE atbalsts kādam no mūsu ekspertiem?