Eaton Fuller Guide Fabhtcheartú Tarchurtha

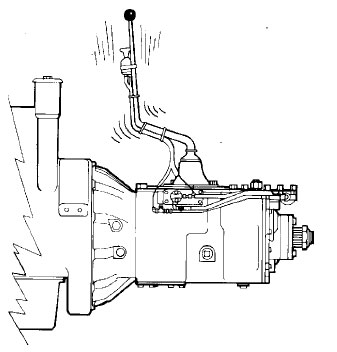

Guide to servicing and repairing Eaton Fuller heavy-duty truck transmission, Cúnamh a aimsiú ar an cheist na trioblóide tarchurtha, analyze the cause and make necessary repairs for 7, 8, 9, 10, 13, 15 agus 18 luas tarchuir Eaton. For more in-depth assistance refer to your transmission model service manual or give us a call at 877-776-4600. Is é an fheidhm tarchuir a aistriú go héifeachtach an t-inneall chumhacht, ó thaobh chasmhóiminte, le rothaí ar chúl na feithicle. Is chasmhóiminte an casta nó fórsa ciorclach seachadadh ag an t-inneall ar flywheel. cóimheasa giair an tarchur a mhéadú nó a laghdú chasmhóiminte brath ar na ceanglais is gá chun bogadh nó a thosú an t-ualach. Giaráil méadú freisin nó laghdú luas. Na cóimheasa giair a spásáil i gceart ionas go mbeidh an t-inneall ag feidhmiú ina raon ISN is éifeachtaí le hathruithe luas forásach. Chun freastal ar riachtanais na feithicle, Ní mór an tarchur bheith cóimheasa íseal go leor chun tús a chur leis feithicil atá ag gluaiseacht, gluaiseacht a choimeád ar bun suas-grád, agus a choinneáil ar an t-inneall a oibríonn ina raon buaic-éifeachtacht. An tarchur, freisin, Ní mór modh éasca a roghnú giair a chur ar fáil.

Treoir Fabhtcheartú do na samhlacha a tharchur Eaton Fuller a leanas:

Gearáin Tarchurtha Common

Chreathadh

Although the effects of vibration will show up in the transmission, vibration usually originates somewhere else in the drive train. Vibration can usually be felt or heard by the driver; ach, i gcásanna áirithe, transmission damage caused by vibration will occur without the driver’s knowledge.

Roinnt Fadhbanna Tarchuir Mar gheall ar Drive Train Chreathadh:

- Creathanna Gear ag díomhaoin

- Gear & shaft splines (fretted)

- torann

- Bearings fretted

- Arís agus arís eile sceitheadh séala cúil

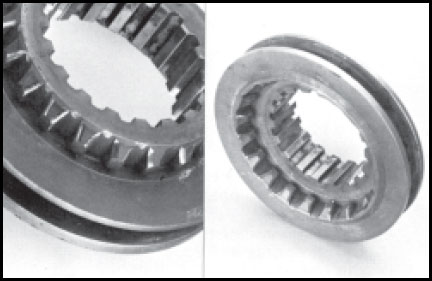

- bioráin synchronizer briste nó scaoilte

- loosening leanúnach ar capscrews, lúibíní agus feistí suite

- Caite seafta Spine Caith

- Worn universal joints (Gan symptom tarchurtha, ach tháscaire chreathadh.)

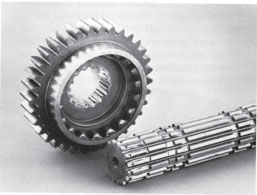

Splíonaí fretted

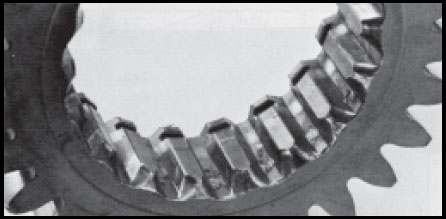

Broken Pins Synchronizer

Ionchur Caith Splíona

Common causes of vibration include driveline imbalance or misalignment, rothaí nó drumaí coscáin unbalanced, inneall ag rith garbh, ghairis inneall briste nó caite agus fionraí caite.

Gear Slipout agus Jumpout

Tosaigh Alt

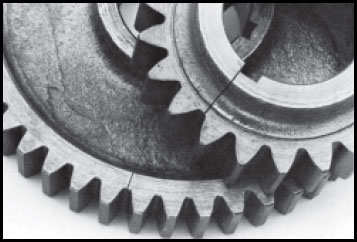

Nuair a clutch sleamhnáin ar athraíodh a ionad a bheith rannpháirteach le trealamh mainshaft, Ní mór na fiacla cúplála comhthreomhar. Beidh barrchaolaithe nó caite fiacla clutching iarracht a dhéanamh "siúl" seachas mar a rothlú an trealamh. Faoi na coinníollacha ceart, Beidh slipout mar thoradh. Tá cuid de na coinníollacha seo a:

- Tarchur suite héalárnach le píolótach flywheel inneall.

- clashing fearas iomarcach a giorraíonn fiacla clutching.

- coigeartú mhícheart nasc rialaithe athrú iargúlta mar thoradh rannpháirtíocht páirteach. Chomh maith leis sin seiceáil do naisc scaoilte agus bushings caite.

Fiacla clutching snubbed

Gear fiacla ag caitheamh le barrchaolú clutching.

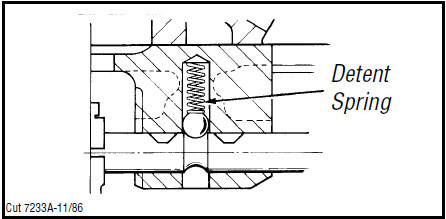

DETENT Spring

brú Gan dóthain ar liathróid DETENT ón lag nó briste earrach DETENT.

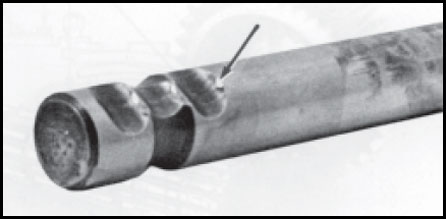

Caite Yoke Bar

Róchaitheamh ar DETENT notch ar barra yoke

Coinníollacha An féidir Go Cúis Jumpout

- Breise luamhán athrú trom agus fada a swing, pendulum faisean, oibriú thar tír-raon míchothrom. gníomh whipping an luamhán overcomes teannas earrach DETENT.

- Rialuithe Meicniúla iargúlta leis an máistir suite ar an fráma. Is féidir Gluaiseacht choibhneasta idir pacáiste inneall-tarchurtha agus fráma bhfeidhm tarchur as fearas. Caite nó ghairis innill briste mhéadú ar na héifeachtaí ar an coinníoll seo.

Auxiliary Alt

Slipout in the auxiliary section may be caused by the clutching teeth being worn, barrchaolaithe, nó nach bhfuil ag gabháil go hiomlán. These conditions cause the clutch gear to “walk” out of engagement as the gears turn.

Causes of these types of clutching defects are clashing or normal wear after long life. Vibrations set up by an improperly aligned driveline and low air pressure add to the slipout problem.

Jumpout in the auxiliary section usually occurs with the splitter gear set. If torque is not sufficiently broken during splitter shifts, the sliding clutch gear may not have enough time to complete the shift before torque is reapplied to the gears. Toisc go bhfuil chasmhóiminte reapplied, the partially engaged clutch gear “jumps” out of the splitter gear. Since the gears have torque applied to them, damage will be done to the clutching teeth of the mating gears.

Feasacht & rochtain feabhsaithe crua

The effort required to move a gear shift lever from one gear position to another varies. If too great an effort is required it will be a constant cause of complaint from the driver.

Tá formhór na ngearán le naisc chineál iargúlta a úsáidtear i bhfeithiclí cabover-inneall. Before checking the transmission for hard shifting the remote linkage should be inspected. Linkage problems stem from worn connections or bushings, ceangailteach, improper adjustment, lack of lubrication on the joints or an obstruction which restricts free movement. D'fhonn a chinneadh má tá an tarchur féin an chúis a aistriú crua, bain an luamhán athrú nó nascadh ó bharr an tarchuir. ansin, move the shift blocks into each gear position using a pry bar or screwdriver. If the yoke bars slide easily, Is é an deacracht leis an tionól nasc. If the trouble is in the transmission, it will generally be caused by one of the following:

- Splines of sliding clutch gear binding on mainshaft as a result of a twisted mainshaft key, bent shift yoke or bowed mainshaft key.

- barraí yoke ceangailteach sa bharra tithíochta mar thoradh ar tithíochta scáinte, níos mó ná-torqued lockscrew bloc athrú, sprung yoke bar, or swelled areas of the yoke bar.

Má tharlaíonn aistriú crua ach sa chéad agus droim ar ais, the shift block detent plunger movement may be restricted. This can result from burrs on the plunger, or from overtightening the plunger spring plug. With the plunger blocked in the depressed position, the plug should be tightened until it bottoms out against the spring, ansin tacaíocht amach 1/4 chun 1/2 cas.

Níor cheart clashing Gear a mheascadh le aistriú crua. Gear clashing occurs when an attempt is made to engage the clutch gear before it has reached synchronization with the mainshaft gear.

Teas

The transmission operating temperature should never exceed 250°F (120° C) ar feadh tréimhse fhada ama. Má dhéanann sé, the oil will breakdown and shorten transmission life.

Mar gheall ar an fhrithchuimilt na codanna ag gluaiseacht, transmissions will produce a certain amount of heat. In most cases normal operating temperature is approximately 100°F (40° C) above ambient. Heat is dissipated through the transmission case. When conditions prevent the proper dissipation of heat, then overheating occurs.

Roimh seiceáil le haghaidh cúiseanna féideartha róthéamh, the oil temperature gauge and sending unit should be inspected to make sure they are giving correct readings.

Causes of Overheating

1. lubrication míchuí. leibhéal ola ró-íseal nó ró-ard, wrong type of oil, or an operating angle of more than 12 céimeanna.

2. Ag feidhmiú go leanúnach faoi 20 MPH.

3. RPM Ard inneall.

4. sruth aeir teoranta timpeall tarchuir, due to the transmission being “boxed in” by frame rails, deck lids, dabhcha breosla agus lúibíní gléasta, or by a large bumper assembly.

5. sceithchóras ró-aice le tarchur.

6. teocht chomhthimpeallach ard.

7. Ard horsepower, oibríocht overdrive.

8. Coasting síos an cnoc leis an clutch depressed.

I gcásanna áirithe, an external oil cooler kit can be used to correct overheating problems.

Tá Tarchuir Coolers Ola:

molta

- Le innill de 350 H.P. and above with overdrive transmissions

Ag teastáil

- le innill 399 H.P agus os a chionn le overdrive

tarchuir agus GCWs thar 90,000 lb.. - le innill 399 H.P. agus os a chionn agus 1400 Lbs.-Ft.

nó chasmhóiminte níos mó - le innill 450 H.P. agus os a chionn

Torann Tarchur

There will always be a certain level of noise due to the normal transmission operation. ach, excessive noise or unusual noise such as a whine, growl, or squeal indicates some kind of a problem.

The transmission itself can be the cause of excessive or unusual noise. chomh maith leis sin, noise can originate elsewhere in the vehicle, ach a phiocadh suas agus amplified ag an tarchuir.

1. Knocking nó thudding

- Gears - Bumps nó swells ar fiacla fearas. Such bumps or swells can be removed with a hone or small hand grinder; these areas can be identified as highly polished pots on the face of the gear tooth. Go ginearálta, this noise is more prominent when the gear is loaded; dá bhrí sin, the problem gear can be located as the noise occurs in a specific gear position. Bumps or swells are caused by improper handling of gears before or during assembly.

- bearings – Noise comes in at low shaft speeds in any position. It is caused by bearings with damaged balls or rollers, or with pitted and spalled raceways.

- scáinte Gear – A gear cracked or broken by shock loading or by pressing on shaft during installation will produce this sound at low speeds. Ag luas ard a bheidh le howl bheith i láthair.

2. High Pitched Whine or Squeal

- Gear Wear - Toradh na gnáth chaitheamh fearas, including gear tooth pitting from excessive use. In advanced deterioration, Beidh a howl mar thoradh.

- Mismatched Gear Sets – Such gear sets are identified by an uneven wear pattern on the face of gear teeth.

- Bearings - "pinch" bearings, having insufficient axial or radial clearance

3. growling

- Timing Error – Improper timing of the transmission during reassembly, or improper timing due to gear turning on the countershaft. Both conditions produce an error in tooth spacing.

Causes of Transmission Noise Originating Elsewhere in Vehicle:

- inneall réchasta Rough. (féach Creathanna fearas)

- torann oibriúcháin Inneall.

- Clutch driven plates in which the dampening action of springs or rubber blocks has been eliminated by wear set or fracture.

- Driveline as cothromaíocht.

- uillinneacha chomhoibrithe neamhionann.

- crosa Caite Na hailt uilíocha.

- bearings ionad scaoilte nó caite.

- fiacla caite nó pitted ar fearas fáinne agus pinion an acastóra tiomána.

- teip bhfuil acastóir cúil.

- Rothaí as cothromaíocht.

- bhfuil pivot earrach Caite.

- Loose "U" boltaí.

- Drumaí coscánaithe warped nó as cothromaíocht.

Treoirlíne Tarchuir Troubleshooter ar

Following is a basic procedure guideline for troubleshooting transmissions:

- Cigireacht Réamh

- Bhreathnóireachta Pearsanta – look for signs of misuse such as broken mounts, feistis nó lúibíní; check airlines.

- Ceist an Úinéir nó Oibreoir – gather information on operating conditions and vehicle use, ar stair na faidhbe, and on shifting characteristics if affected.

- Bailigh Stair Aonaid – including maintenance and lubrication procedures, teipeanna seo caite, agus míleáiste nó uair an chloig de úsáid.

- Tarchur disassemble

- Coinnigh sampla ola maidir le heisíontais, seiceáil más gá.

- Le linn disassembly, check for incorrectly installed parts, páirteanna ar iarraidh, and nongenuine parts.

- Glan agus cigireacht ar gach píosa dlúth.

- Socraigh Cineál Failure

- A chinneadh agus Cause ceart Failure

The Troubleshooter’s Guideline Chart is used to locate and correct transmission problems. To use the guideline,

1) Aimsigh an bhfadhb tarchuir sna boscaí thíos

2) Hover over the box to see the possible problem and take note of the numbers next to the possible cause

3) Déan tagairt don liosta thíos agus faigh an líon comhfhreagrach liostaithe in aice leis an bhfadhb. Beidh an uimhir meaitseáil as an liosta a insint duit an ceartú is féidir.

4) Is féidir go mbeadh chúis is féidir níos mó ná aon agus a cheartú is féidir do gach fadhb.

Ceartuithe Féideartha:

- Treoir a tiománaí ar theicnící tiomána cuí.

- páirteanna Ionadaigh (after trying other listed possible corrections).

- Scaoil frithdhúnadh scriú agus retighten le chasmhóiminte cuí.

- Cuardaigh le haghaidh damáiste dá bharr.

- Smooth le páipéar éimir.

- Athshocraigh do sonraíochtaí cuí.

- Suiteáil codanna atá ar iarraidh.

- Seiceáil aerlínte nó píobáin.

- Níos doichte chuid.

- Ceart an srian.

- athsheiceáil uainiú.

- pháirt.

- Cuir iarratas isteach silicone scannán tanaí.

- Cuir iarratas isteach shéalaithe.

aon cuid tarchurtha ní mór duit ní mór dúinn é! loingseoireachta lá céanna ar fáil, ar fud an domhain.

MÓR TACAÍOCHT SAOR IN AISCE ÓN ÁR SHAINEOLAITHE AMHÁIN DE?